In the ever-evolving landscape of automation solutions, gearedmotors have emerged as indispensable components, offering enhanced efficiency and performance for a wide range of applications. As industry expert Dr. Emily Carter, a renowned mechanical engineer at Tech Innovations, states, "The integration of gearedmotors into automated systems not only optimizes energy consumption but also significantly improves operational reliability." This insight underscores the critical role gearedmotors play in contemporary automation technologies.

The advantages of gearedmotors are manifold, supporting varied tasks from industrial machinery to robotics. Their design allows for reduced speed and increased torque, making them ideal for applications where precision and power are paramount. As businesses strive for greater productivity and sustainability, understanding how gearedmotors can be effectively utilized is essential for maintaining a competitive edge in the market.

Furthermore, with the increasing demand for automation across different sectors, the innovative developments in gearedmotor technology are paving the way for smarter, more efficient systems. By exploring the advantages of gearedmotors, we can unlock new possibilities for automation solutions that not only enhance performance but also contribute to a greener future.

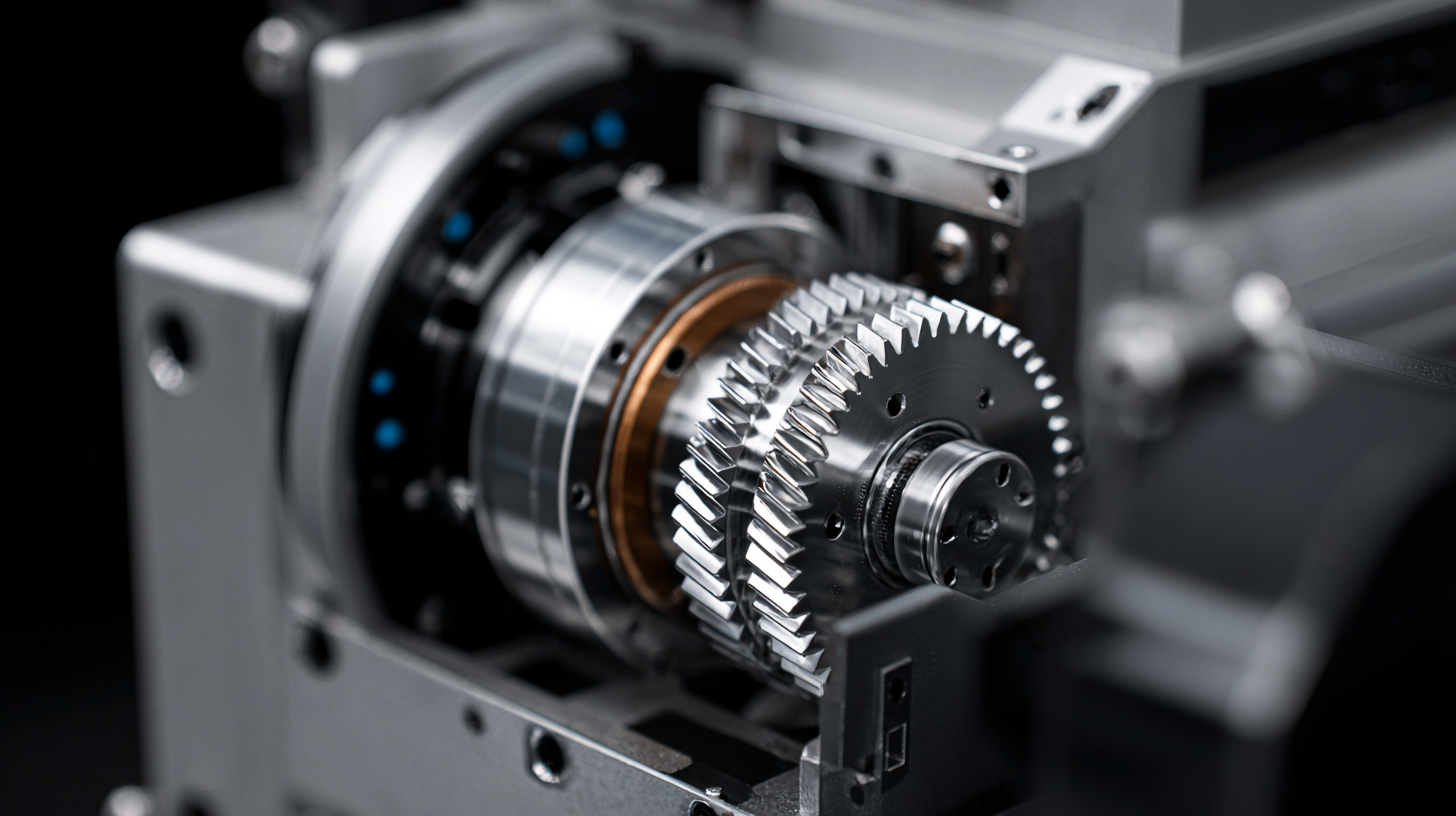

Geared motors have become essential components in modern industrial automation, streamlining processes and enhancing efficiency. These devices combine a motor with a gearbox, allowing for a reduction in speed and an increase in torque, which is particularly beneficial in applications that require precise control over movement. By reducing the required power and increasing operational efficiency, geared motors help companies optimize their machinery, resulting in lower operational costs and improved productivity levels.

Geared motors have become essential components in modern industrial automation, streamlining processes and enhancing efficiency. These devices combine a motor with a gearbox, allowing for a reduction in speed and an increase in torque, which is particularly beneficial in applications that require precise control over movement. By reducing the required power and increasing operational efficiency, geared motors help companies optimize their machinery, resulting in lower operational costs and improved productivity levels.

Tip: When selecting a geared motor, consider the specific requirements of your application, including load capacity, speed, and torque. This ensures that the motor you choose can meet the demands of your automation processes without compromising performance.

Furthermore, geared motors are designed to operate smoothly, reducing wear and tear on machinery. This contributes to longer service life and less downtime for repairs, making them a reliable choice in high-demand environments. Their versatility allows for use in a variety of sectors, from manufacturing to logistics, making them integral to the advancement of automation technologies.

Tip: Regular maintenance of geared motors can further enhance their lifespan and efficiency. Schedule periodic checks to ensure that the lubrication and components remain in optimum condition, mitigating potential issues before they become significant problems.

Gearedmotors play a pivotal role in modern automation solutions, particularly in enhancing energy efficiency. By integrating gear systems with electric motors, gearedmotors effectively convert electrical energy into mechanical energy while optimizing performance. The gears help in reducing motor speed while increasing torque, which allows for more efficient operation when driving heavy loads. This reduction in speed not only contributes to lower energy consumption but also prolongs the life of the motor by minimizing wear and tear.

Moreover, the design flexibility of gearedmotors enables them to be tailored to specific applications, further enhancing their energy efficiency. By selecting the appropriate gear ratio and motor size, industries can achieve precise control over their systems, leading to improved operational efficiency. This customization means that gearedmotors can operate at optimal levels, reducing energy wastage and contributing to more sustainable manufacturing processes. As industries increasingly prioritize energy conservation, the adoption of gearedmotors represents a significant step towards more sustainable and efficient automation solutions.

The choice between gearedmotors and traditional motors is pivotal for industries looking to enhance their automation processes. Gearedmotors offer unique advantages, particularly in applications requiring high torque at low speeds. This is essential in modern automation solutions where precision and efficiency are paramount. With an integrated gearbox, gearedmotors can deliver more power while maintaining a compact size, allowing for smoother operation in constrained spaces. This feature significantly reduces energy consumption, contributing to overall cost savings for businesses.

In contrast, traditional motors, while reliable, often face limitations in torque and speed adaptability. They may require additional components, such as external gearboxes, to achieve similar performance levels as gearedmotors, which can complicate system designs and increase installation time. As industries increasingly demand efficient and versatile solutions, gearedmotors are poised to dominate the market, aligning with the projected growth of the low voltage electric motor sector from $67.11 billion in 2025 to $108.09 billion by 2032, fueled by a compound annual growth rate of 7.05%. The comparative advantages of gearedmotors are clear, making them a favorable choice in today's automation landscape.

In today's rapidly evolving automation landscape, geared motors have emerged as pivotal components that enhance the performance and efficiency of various systems. According to the market research firm Research and Markets, the global geared motor market is projected to reach approximately $14 billion by 2026, growing at a CAGR of around 6%. This growth is driven by the increasing demand for energy-efficient and compact systems that can manage higher loads without sacrificing performance. Innovations in geared motor technology, including advanced materials and smart automation features, are addressing the modern industry’s needs for reliability and adaptability.

Recent advancements include the integration of IoT capabilities in geared motors, allowing for real-time monitoring and predictive maintenance. This trend is underscored by a report from Mordor Intelligence, which states that the deployment of smart motors is expected to grow significantly as industries seek to optimize their operations and reduce downtime. Furthermore, the development of high-efficiency geared motors that comply with strict environmental regulations not only enhances sustainability but also decreases operational costs. As manufacturing processes become more complex, these technological innovations in geared motors will remain crucial to sustaining competitiveness in the automation sector.

The implementation of gearedmotors in various automation projects has yielded impressive results across multiple industries. One notable case study is in the automotive sector, where a manufacturing plant integrated gearedmotors into its assembly line. By utilizing high-torque gearedmotors, the plant significantly increased its production speed and efficiency. The precise control offered by these motors allowed for smoother operations, reducing the risk of errors during assembly and ensuring consistent product quality.

Another compelling example comes from the food processing industry, where gearedmotors were employed in conveying systems. The use of gearedmotors not only optimized the speed and accuracy of ingredient handling but also enhanced energy efficiency. By coupling gearedmotors with advanced control systems, companies were able to minimize waste and energy consumption, leading to lower operational costs. These case studies illustrate how gearedmotors can solve complex automation challenges, proving their value in modern industrial applications.

| Project Name | Industry | Application | Gearedmotor Specification | Benefits Achieved |

|---|---|---|---|---|

| Automated Packaging Line | Food and Beverage | Conveyor System | High Torque, Low RPM | Increased Efficiency and Reduced Downtime |

| Automated Guided Vehicles | Logistics | Robot Movement | Compact Size, High Efficiency | Improved Maneuverability and Load Capacity |

| Textile Machine Automation | Textiles | Fabric Cutting and Feeding | Variable Speed Control | Higher Precision and Reduced Waste |

| Robotic Arm Assembly | Manufacturing | Assembly Line | High Precision, High Load Capacity | Enhanced Production Rate and Accuracy |

| Material Handling System | Construction | Lifting and Transporting | Heavy-Duty Torque | Increased Safety and Load Management |