Zhengke High-Quality DC Motors: Reliable Performance from a Trusted Manufacturer

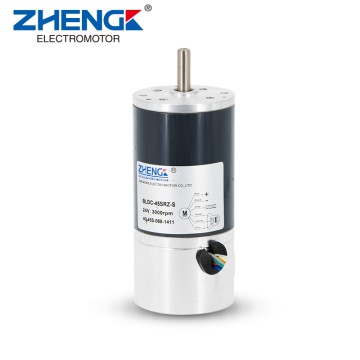

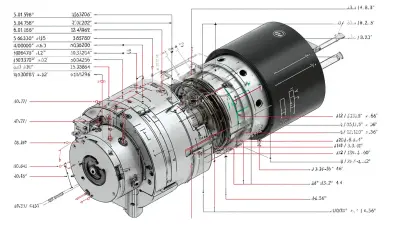

Discover the exceptional performance of DC motors from Zhejiang Zhengke Electromotor Co., Ltd. Engineered for precision and reliability, our DC motors are ideal for a wide range of applications, including robotics, electric vehicles, and industrial machinery, These motors operate on direct current, providing High Torque at low speeds, making them perfect for demanding environments. Our innovative designs ensure efficiency and longevity, reducing maintenance costs and downtime, With a focus on quality, each motor is rigorously tested to meet the highest industry standards, ensuring seamless integration into your projects. Whether you need compact models for space-constrained designs or robust versions for heavier applications, we have the solutions tailored to your needs, Choose Zhejiang Zhengke Electromotor Co., Ltd. for DC motors that combine cutting-edge technology, exceptional performance, and unparalleled support. Elevate your operations with our trusted products, designed to drive your success forward

Methods To choose Dc Motor Operation in 2025 Custom Solutions,

Choosing the right DC motor for your application in 2025 requires a thoughtful approach, especially with the rise of customized solutions tailored to meet specific operational needs. As a leader in the manufacturing of gear DC motors, we understand that the selection process must account for variables such as efficiency, torque, speed, and size. Our strong R&D team leverages advanced equipment and engineering expertise to help global procurement professionals navigate these considerations, ensuring that the motors not only meet technical specifications but also align with broader project goals. In today’s market, customization is key. Our extensive experience in developing tailored solutions means we can address unique requirements, from variable speed applications to compact designs for space-constrained environments. Whether you need a high-torque motor for heavy-duty applications or a lightweight option for portable devices, we provide an array of customizable features. With skilled engineers and workers committed to quality, we deliver high-performance products backed by professional technology support that enhances usability and efficiency. As you explore options for DC motor operations in 2025, consider a partner with the capability to adapt to your specific needs. Our commitment to innovation and excellence ensures that we not only meet but exceed the expectations of our global clients, empowering them to succeed in an increasingly competitive landscape. Make the right choice for your motors, and let us help you realize your project’s full potential.

Methods To Choose DC Motor Operation in 2025 Custom Solutions

| Method | Description | Efficiency (%) | Cost ($) | Applications |

|---|---|---|---|---|

| Pulse Width Modulation (PWM) | Controls motor speed by varying the duty cycle of a signal. | 90 | 50 | Robotics, Electric Vehicles |

| Closed Loop Control | Uses feedback to maintain desired speed or position. | 85 | 120 | Industrial Automation, CNC Machines |

| Sensorless Control | Estimates motor position and speed without sensors. | 80 | 70 | Home Appliances, Fans |

| Field Weakening | Increases speed by weakening the magnetic field. | 75 | 100 | High-speed Applications, Electric Bicycles |

| Commutation Techniques | Adjusts the phase of current to the motor windings. | 88 | 80 | Electric Vehicles, Robotics |

Top 10 Dc Motor Operation Service Manufacturer

D

Daniel Lee

The craftsmanship is excellent. I appreciated the outstanding support from their knowledgeable team.

19 June 2025

H

Harper Allen

The quality is remarkable! Their customer service had the expertise to handle my concerns effortlessly.

26 May 2025

J

Jacob Young

A high-quality choice! The response from the support team was prompt and very professional.

03 June 2025

A

Alexander Scott

An outstanding quality product! The after-sales team were true experts who helped me a lot.

12 June 2025

R

Ryan Baker

Strongly recommend! The product quality is matched by the excellent after-sales service.

24 May 2025

S

Samantha Hill

What an amazing product! The professionalism of the staff made all the difference.

03 July 2025