Wholesale Electric Gear Reduction Motors - Trusted Suppliers for Reliable Products

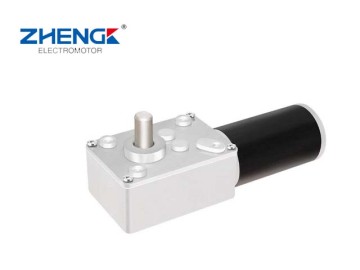

Zhejiang Zhengke Electromotor Co., Ltd. proudly presents its advanced Electric Gear Reduction Motor, designed to meet the demands of various industrial applications. This high-performance motor combines efficiency and durability, offering precise speed control and exceptional torque output. Engineered with cutting-edge technology, our gear reduction motor minimizes energy consumption while maximizing power delivery, making it an ideal choice for numerous devices in manufacturing, automation, and transportation, Constructed with high-quality materials, this motor is built to withstand rigorous conditions and long operational hours, ensuring reliable performance over time. The compact design not only saves space but also simplifies installation, making it suitable for both new projects and retrofitting existing systems, With a focus on innovation and customer satisfaction, Zhejiang Zhengke Electromotor Co., Ltd. guarantees superior quality and performance in every product. Choose our Electric Gear Reduction Motor to enhance your operational efficiency and drive your projects forward with confidence

Expert Tips For Electric Gear Reduction Motor Factory Custom Solutions,

In the world of electric gear reduction motors, finding the right solution for your specific needs can be a daunting task. At our factory, we leverage our rich experience in manufacturing various gear Dc Motors, coupled with a strong R&D team and advanced equipment, to deliver custom solutions tailored to your requirements. Whether you are looking for a standard motor or a specialized design, our skilled engineers and workers are dedicated to ensuring high-quality manufacturing that meets the highest industry standards. Our commitment to excellence enables us to provide customers with not just superior products, but also professional technological support throughout the entire process. From the initial consultation to the final product delivery, we prioritize your satisfaction and work closely with you to refine every aspect of the gear reduction motor. By choosing our factory for your needs, you gain access to a wealth of expertise and innovative solutions designed to enhance the efficiency and performance of your applications. With the increasing demand for customized solutions in the global market, our factory stands out as a partner who understands the nuances of your industry. We are here to help you navigate the complexities of motor selection, offering expert tips and insights that will empower you to make informed decisions. Let us transform your visions into reality with our competitive pricing, timely delivery, and unmatched quality. Partner with us today and experience the difference that expert craftsmanship and dedicated service can make for your business.

Expert Tips For Electric Gear Reduction Motor Factory Custom Solutions

| Tip No. | Expert Tip | Application | Benefits |

|---|---|---|---|

| 1 | Conduct a thorough requirement analysis before finalizing the design. | Custom motors for robotics. | Ensures optimal performance tailored to specific tasks. |

| 2 | Select high-quality materials to enhance durability. | Industrial machinery. | Increases lifespan and reduces maintenance costs. |

| 3 | Utilize precise gear ratios for efficiency. | Automated assembly lines. | Improves overall system efficiency and productivity. |

| 4 | Incorporate thermal management solutions. | Heavy-duty applications. | Prevents overheating and prolongs motor life. |

| 5 | Consider variable speed options for flexibility. | Conveyor systems. | Enhances adaptability for different operational needs. |

How To Source Electric Gear Reduction Motor Guarantees Peak Performance Custom Solutions,

M

Mia Wilson

High-quality product and the after-sales service made me feel valued as a customer.

24 May 2025

C

Charlotte Allen

I love this item! The quick service response and knowledgeable staff were commendable.

28 May 2025

A

Anabelle Clark

What a fantastic product! The service team displayed expertise that put my mind at ease.

15 June 2025

S

Sofia Allen

Incredible quality! The support team demonstrated impressive knowledge and responded timely.

12 May 2025

O

Oliver Reed

Excellent quality! The proactive customer service made me feel valued.

08 May 2025

C

Colton Rogers

Phenomenal experience! The support staff demonstrated their expertise with me.

24 June 2025