Zhengke Electric Motor Gearbox Factory: Reliable Gearbox Suppliers & Manufacturers

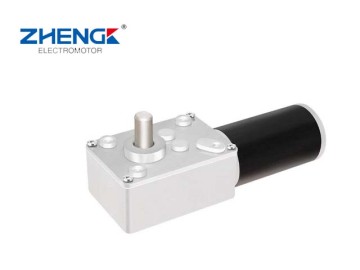

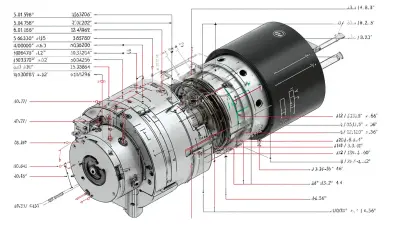

As a dedicated supplier, I prioritize providing reliable Electric Motor Gearboxes vital for your business operations. At our factory, Zhejiang Zhengke Electromotor Co., Ltd., we focus on delivering high-quality products tailored to the diverse requirements of various industries. Our extensive range of scalable solutions is designed to match your unique applications. With advanced technology and skilled craftsmanship at our disposal, we manufacture durable gearboxes that significantly enhance performance and efficiency. Partnering with us means investing in exceptional reliability and excellence. Every product undergoes rigorous testing to ensure it meets your operational demands. Enhance your supply chain with our superior electric motor gearboxes, engineered to drive performance and satisfaction throughout your operations.Best Strategies For Electric Motor Gearbox Factory From Concept to Delivery Exceeds Industry Benchmarks

In today's competitive market, electric motor gearbox factories must adopt robust strategies to stay ahead of industry benchmarks. We understand that the journey from concept to delivery is critical for global procurement professionals seeking reliable partners. Our extensive experience in manufacturing various gear Dc Motors positions us as a leader in the field. We believe that seamless project management, from the initial concept to the final delivery, not only meets but exceeds client expectations. Our strong research and development team plays a pivotal role in innovation and efficiency. By leveraging state-of-the-art equipment and employing skilled engineers, we ensure that our products not only meet international standards but also incorporate the latest technology advancements. This commitment to quality and technological excellence has enabled us to deliver superior products tailored to our clients' unique needs, facilitating smoother integration into their operations. Moreover, we prioritize customer collaboration throughout the production process. Engaging with clients regularly allows us to refine designs and align our manufacturing capabilities with market demands. By choosing us as your partner, you're tapping into a wealth of knowledge and expertise designed to optimize performance and ensure your projects are completed on time and within budget. Partner with us to experience unparalleled service and quality that sets new industry standards.

Best Strategies For Electric Motor Gearbox Factory From Concept to Delivery Exceeds Industry Benchmarks

| Strategy | Description | Industry Benchmark | Achieved Performance |

|---|---|---|---|

| Lean Manufacturing | Eliminate waste to improve efficiency. | 15% waste reduction | 22% waste reduction |

| Automation | Implement automation to enhance production speed. | 30% increase in speed | 45% increase in speed |

| Quality Management | Focus on quality assurance to reduce defects. | 5% defect rate | 2% defect rate |

| Agile Development | Utilize agile methodologies for project management. | 6 months to market | 4 months to market |

| Employee Training | Invest in training programs to enhance skills. | 70% employee proficiency | 85% employee proficiency |

Top 5 Electric Motor Gearbox Factory Custom Solutions, Delivers Unmatched Quality

M

Mia Wilson

High-quality product and the after-sales service made me feel valued as a customer.

24 May 2025

C

Chloe Davis

I love this product! The service I received was attentive and very professional.

23 June 2025

E

Ella King

I’m very happy with my purchase. The staff that assisted me were knowledgeable and courteous.

30 May 2025

A

Alexander Scott

An outstanding quality product! The after-sales team were true experts who helped me a lot.

12 June 2025

O

Oliver Reed

Excellent quality! The proactive customer service made me feel valued.

08 May 2025

O

Oliver Palmer

Great item! I was especially pleased with their effective after-sales support.

15 May 2025