Zhengke Quality Gear Reduction Motors | Reliable Manufacturers & Factory Solutions

As a top manufacturer of gear reduction motors, Zhejiang Zhengke Electromotor Co., Ltd. prioritizes performance and durability essential for industrial applications. Our high-quality gear reduction motors are designed to fulfill the varied needs of factories in multiple sectors. With a comprehensive product range, we provide solutions tailored to your requirements, spanning precision control, high torque, and energy efficiency. We emphasize collaboration with our clients to enhance operational efficiency and minimize downtime. Choosing Zhengke means partnering with a company dedicated to innovation, excellence, and customer satisfaction. Contact us today to learn how our superior products can elevate your manufacturing processes.10 Essential Tips For Gear Reduction Motor Manufacturers Supplier Service

When it comes to sourcing gear reduction motors, manufacturers must prioritize reliable supplier service to ensure seamless operations and optimal performance. Here are ten essential tips for manufacturers to enhance their engagement with suppliers, ensuring you receive the best products and support. First, establish clear communication channels. Regular updates on production timelines, potential delays, and product specifications can significantly improve collaboration with suppliers. Next, request detailed documentation of the manufacturing process, including quality assurance practices. This transparency builds trust and allows you to verify that the supplier adheres to high standards. Leveraging a supplier's R&D capabilities is also crucial. A partner with a strong research team, like ours, can help customize solutions to meet specific needs, keeping you competitive in the market. Furthermore, evaluate the supplier’s technological advancements—these play a vital role in the efficiency and quality of the gear reduction motors you purchase. Remember, skilled engineers and advanced equipment can lead to innovative solutions that enhance your product offerings. By focusing on these aspects, global buyers can forge successful partnerships that yield quality gear reduction motors tailored to their operational requirements.

10 Essential Tips For Gear Reduction Motor Manufacturers Supplier Service

| Tip Number | Tip Description | Importance Level | Implementation Timeframe |

|---|---|---|---|

| 1 | Ensure quality control processes are in place for product reliability. | High | Ongoing |

| 2 | Investigate the latest gear reduction technologies to stay competitive. | Medium | Quarterly |

| 3 | Provide excellent after-sales service to build customer loyalty. | High | Immediate |

| 4 | Offer customizable solutions to meet specific client needs. | Medium | 6 months |

| 5 | Maintain a robust supply chain for consistent product availability. | High | Ongoing |

| 6 | Regularly train staff on new technologies and customer service. | Medium | Biannually |

| 7 | Implement eco-friendly practices in manufacturing. | High | 1 year |

| 8 | Engage in active marketing to raise awareness of product offerings. | Medium | Ongoing |

| 9 | Establish partnerships with other manufacturers for better outsourcing. | Medium | 1 year |

| 10 | Continuously evaluate customer feedback for product improvement. | High | Ongoing |

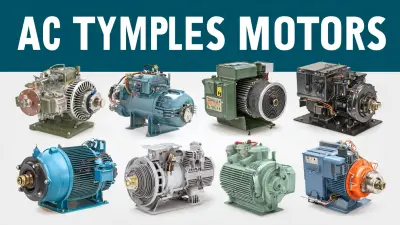

Trending Gear Reduction Motor Manufacturers Pioneers in the Field Supplier

C

Charlotte Allen

I love this item! The quick service response and knowledgeable staff were commendable.

28 May 2025

L

Lila Rivera

This product has surpassed my expectations. Their customer service followed up promptly.

13 June 2025

C

Connor Rivera

Quality is exceptional! The professionalism of the service staff was quite notable.

29 June 2025

S

Sienna James

What a wonderful experience! I appreciated the quality and professional service alike.

12 May 2025

O

Owen Nelson

High-quality item! The after-sales service was very rapid and insightful.

15 June 2025

C

Cassidy Kim

Great quality! Their follow-up support was especially impressive and punctual.

14 May 2025