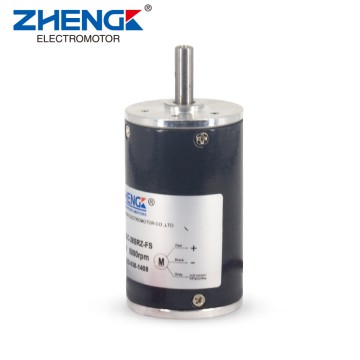

High-Quality DC Motor Drives: Top Zhengke Products & Trusted Suppliers

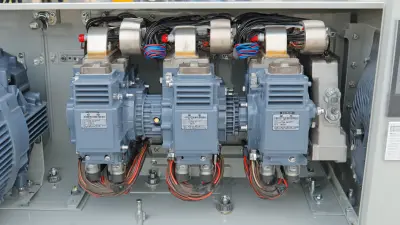

Experience a selection of high-quality DC Motor Drives, specifically engineered for factories that demand reliability and efficiency. With extensive expertise in manufacturing gear DC motors, we are committed to delivering exceptional performance and durability that meet the rigorous requirements of industrial applications. Our state-of-the-art equipment, combined with a dedicated R&D team, fosters continuous innovation, while our skilled engineers uphold strict quality standards throughout the production process. Our diverse range of precision drives and robust motors caters to various needs, making us a preferred partner for manufacturers. Investing in our DC motor drives enhances productivity and minimizes downtime. By choosing our solutions, you not only obtain premium products but also benefit from professional technology support, elevating your operations with tailored motor solutions for your factory.Best Practices For High-Quality Dc Motor Drive Application Winning in 2025

In the competitive landscape of 2025, optimizing the performance and reliability of DC motor drive applications is crucial for businesses looking to gain a significant edge. Understanding the best practices in this field can lead to superior product offerings, enhancing both customer satisfaction and operational efficiency. Companies seeking high-quality gear DC motors must prioritize collaboration with manufacturers that boast extensive experience and a robust research and development (R&D) team. This ensures that the products meet evolving market demands and technological advancements. Our company stands out in this regard, as we leverage advanced equipment, a skilled workforce, and a commitment to innovation. Our engineers and production staff work diligently to create gear DC motors that not only excel in performance but also align with the specific needs of diverse applications. By integrating professional technology and quality control processes, we ensure our products deliver reliability and longevity, essential factors for global procurement managers when selecting suppliers. Investing in high-quality DC motor drives requires a focus on the entire lifecycle, from design and prototype testing to final production and after-sales support. By partnering with experienced manufacturers like us, clients can benefit from tailored solutions and expert guidance. This collaborative approach lays a solid foundation for success in the evolving landscape of motor drive applications, enabling businesses to thrive well into the future.

Best Practices For High-Quality DC Motor Drive Application Winning in 2025

| Practice | Description | Expected Outcome | Implementation Timeline |

|---|---|---|---|

| Use High-Efficiency Motors | Select DC motors designed for high efficiency to reduce energy consumption. | Lower operational costs and improved sustainability. | Short-term (1-2 years) |

| Implement Advanced Control Algorithms | Utilize algorithms like PID, Fuzzy logic, or neural networks for precise motor control. | Enhanced performance and responsiveness. | Medium-term (2-4 years) |

| Incorporate Feedback Systems | Use sensors to monitor parameters such as speed and torque for better control. | Improved accuracy and efficiency of motor operations. | Short-term (1-2 years) |

| Conduct Regular Maintenance | Schedule regular inspections and maintenance to ensure optimal performance. | Minimized downtime and extended motor life. | Ongoing |

| Utilize Simulation Tools | Employ software tools for simulating motor performance under different conditions. | Risk assessment and optimized design parameters. | Medium-term (2-4 years) |

How To Select High-Quality Dc Motor Drive Global Reach Trusted by Pros

M

Mia Wilson

High-quality product and the after-sales service made me feel valued as a customer.

24 May 2025

W

William Wright

Fantastic build quality! The after-sales service staff were extremely helpful and responsive.

06 June 2025

C

Charlotte Allen

I love this item! The quick service response and knowledgeable staff were commendable.

28 May 2025

L

Lily Martinez

I appreciate the quality and the thoroughness of the customer service team.

30 June 2025

I

Isaiah Young

Quality meets expert support! I felt very guided through my purchase.

19 June 2025

C

Colin Lee

Quality that lasts! The service team demonstrated great skill and responsiveness.

05 June 2025