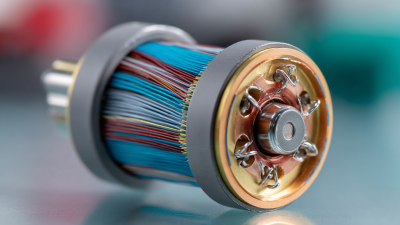

Premium High Torque BLDC Motors from Leading Manufacturers and Factories

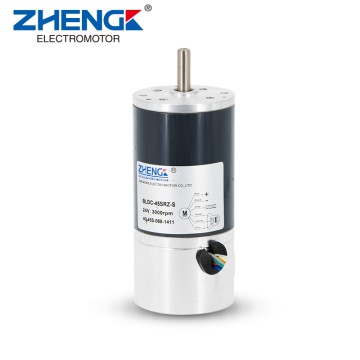

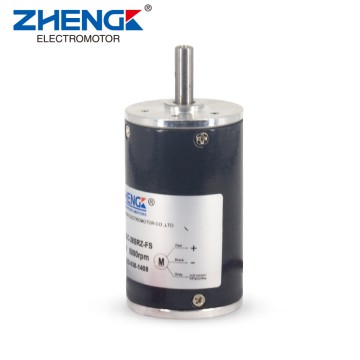

For a dependable high-quality high-torque BLDC solution, you have come to the right resource. At Zhejiang Zhengke Electromotor Co., Ltd., we specialize in providing advanced motor solutions tailored to meet the specific requirements of various industries. Our products are engineered for optimal performance and efficiency, ensuring seamless operation for your projects. With rigorous quality control measures in place, our skilled manufacturers guarantee products that endure demanding conditions. Whether it's for industrial applications, automotive, or consumer electronics, our high-torque Bldc Motors deliver the flexibility you need. Choosing us means receiving not only top-tier products but also outstanding support and service. Propel your business forward with our innovative motor technologies that enhance productivity and reliability.

Proven Methods To High-Quality High Torque Bldc Product in 2025 Factory

In today's rapidly evolving industrial landscape, the demand for high-quality high torque Brushless DC (BLDC) motors is increasingly crucial for manufacturers seeking efficiency and reliability in their applications. At our factory, we leverage our extensive experience in producing various gear DC motors to lead the way in developing cutting-edge BLDC products for 2025 and beyond. Our strong R&D team is dedicated to innovation, ensuring that we remain at the forefront of technology advancements that address the specific needs of our global clientele. Our advanced manufacturing equipment, combined with the expertise of our skilled engineers and workers, guarantees that we deliver not only exceptional products but also comprehensive technical support. We understand that high torque performance requires meticulous attention to detail, which is why each of our BLDC motors undergoes rigorous testing to meet international quality standards. By choosing us as your supplier, you gain a partner committed to enhancing your operational capabilities through reliable and efficient solutions tailored to your unique requirements. As we move towards 2025, our focus on high-quality production and continuous improvement positions us as a preferred choice for global buyers. We invite procurement professionals to explore how our innovative BLDC motor solutions can drive their projects forward, ensuring they remain competitive in an increasingly demanding marketplace. Together, let’s harness the power of technology to achieve unprecedented success.

Proven Methods To High-Quality High Torque BLDC Product in 2025 Factory

| Method | Description | Expected Outcome | Implementation Cost | Timeframe |

|---|---|---|---|---|

| Advanced Motor Design | Utilizing CAD tools to design optimized rotor and stator shapes. | Increased efficiency and torque output. | $50,000 | 6 months |

| High-Quality Materials | Sourcing rare earth magnets and high-grade steel. | Improved durability and performance. | $75,000 | 3 months |

| Precision Manufacturing | Adopting CNC and automated assembly processes. | Enhanced product consistency and reduced waste. | $100,000 | 8 months |

| Comprehensive Testing | Implementing rigorous quality control protocols. | Ensured reliability and compliance with standards. | $30,000 | 2 months |

| Software Optimization | Enhancing electronic control algorithms for better performance. | Improved torque control and responsiveness. | $20,000 | 4 months |

Effective Ways To High-Quality High Torque Bldc Product Global Reach Dominates

S

Sophia Baker

Excellent product! The staff provided great assistance and were very knowledgeable about the details.

31 May 2025

A

Ava Thompson

Very well made! The after-sales staff provided thorough explanations and were very friendly.

10 May 2025

W

William Wright

Fantastic build quality! The after-sales service staff were extremely helpful and responsive.

06 June 2025

V

Victoria Price

High-quality product! The professional support team made everything effortless.

18 June 2025

R

Riley Parker

Fantastic quality product! Very responsive support team handled my inquiries very well.

28 May 2025

G

Grayson Thompson

Impressive build! The customer service team was wise and attentive.

08 June 2025