High-Quality Micro Metal Gear Products from Zhengke Factory - Reliable Performance

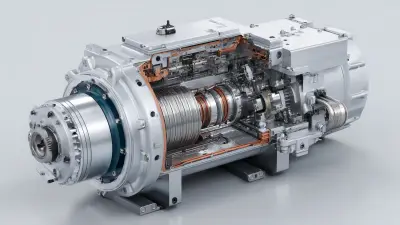

Explore the precision engineering of Micro Metal Gear, a cutting-edge product from Zhejiang Zhengke Electromotor Co., Ltd. Designed for applications requiring high performance in compact spaces, these micro gear motors are engineered to deliver exceptional torque and speed while maintaining energy efficiency, Crafted with top-quality materials, Micro Metal Gear ensures durability and reliability in various industrial and consumer applications, including robotics, automotive systems, and automation equipment. With advanced technology and meticulous attention to detail, these gear motors provide smooth operation and precise control, making them ideal for intricate tasks where accuracy matters, Zhejiang Zhengke Electromotor Co., Ltd. prides itself on innovative solutions that meet the evolving needs of the market. The Micro Metal Gear stands as a testament to the company’s commitment to excellence and customer satisfaction. Elevate your projects with our state-of-the-art micro gear motors, where small size meets powerful performance

Advantages Explained Micro Metal Gear Winning in 2025 Service

In a rapidly evolving marketplace, the demand for high-quality micro metal gears continues to escalate, especially as industries embrace automation and precision engineering. Our extensive experience in manufacturing gear Dc Motors positions us at the forefront of this trend. We leverage our skilled R&D team, advanced equipment, and dedicated engineers to produce micro metal gears that not only meet but exceed customer expectations. In 2025, we anticipate a significant shift towards more efficient and compact designs, making our products essential for various applications. What sets us apart is our commitment to innovation and quality. Our micro metal gears are engineered with precision, ensuring reliability and performance across diverse industries. Global procurement leaders will find value in our flexible manufacturing capabilities, allowing for tailored solutions to meet specific needs. With a focus on sustainable practices, our production processes also minimize environmental impact, aligning with the growing demand for responsible sourcing in today's market. Partnering with us means accessing a wealth of expertise and a product line designed for performance and longevity. As we move into 2025, we are confident that our micro metal gear solutions will not only fulfill current market needs but also anticipate future challenges, providing our customers with a competitive edge in their respective fields. Choose us for a reliable partnership that empowers your business with cutting-edge technology and superior quality.

Advantages Explained Micro Metal Gear Winning in 2025 Service

| Dimension | Description | Advantage |

|---|---|---|

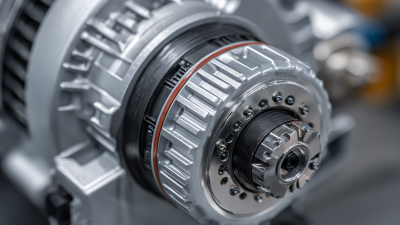

| Size | Compact design suitable for small applications | Allows integration in space-constrained environments |

| Weight | Lightweight materials used for construction | Reduces overall product weight, enhancing mobility |

| Durability | Resistance to wear and tear | Longer lifespan and reduced maintenance costs |

| Performance | High-efficiency transmission | Improved torque delivery and energy efficiency |

| Customization | Tailored solutions for various applications | Flexible designs meet specific user needs |

| Noise Level | Low-noise operation | Improved user comfort in sensitive environments |

How-To Guide Micro Metal Gear Supplier Factory-Direct Excellence

E

Ella King

I’m very happy with my purchase. The staff that assisted me were knowledgeable and courteous.

30 May 2025

C

Colton Rogers

Phenomenal experience! The support staff demonstrated their expertise with me.

24 June 2025

A

Autumn Lee

Great product! Appreciate the knowledgeable support team who helped me thoroughly.

23 May 2025

C

Chase Campbell

Love the quality! They followed up diligently, making sure I was satisfied.

09 June 2025

C

Cecilia Adams

Amazing product! The support I received was attentive, ensuring everything went smoothly.

03 June 2025

A

Aiden Scott

This purchase was top-notch! Their customer service were truly experts in their field.

26 June 2025