Analysis of Causes for DC Motor Malfunctions

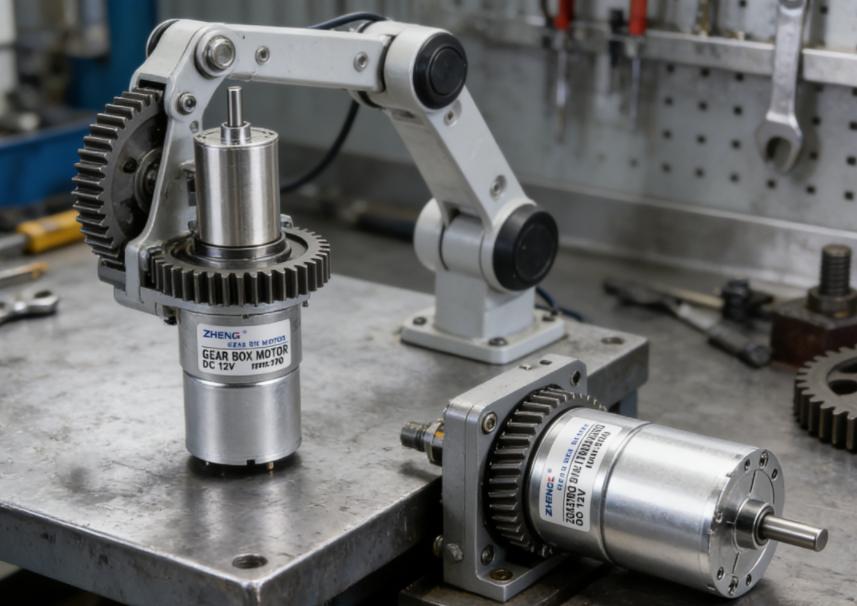

DC motorsare widely used across numerous industries and applications due to their simplicity, reliability, and high efficiency. However, operational abnormalities in DC motors can lead to various issues, potentially causing system failures or shutdowns. Therefore, understanding the causes of Dc Motor Operational abnormalities and taking appropriate measures to prevent or mitigate them is crucial.

One of the most common problems with DC motors is operational abnormality, which can result in a range of issues such as noise, vibration, overheating, and even motor failure. The causes of DC motor operational abnormalities can be broadly categorized into mechanical and electrical factors.

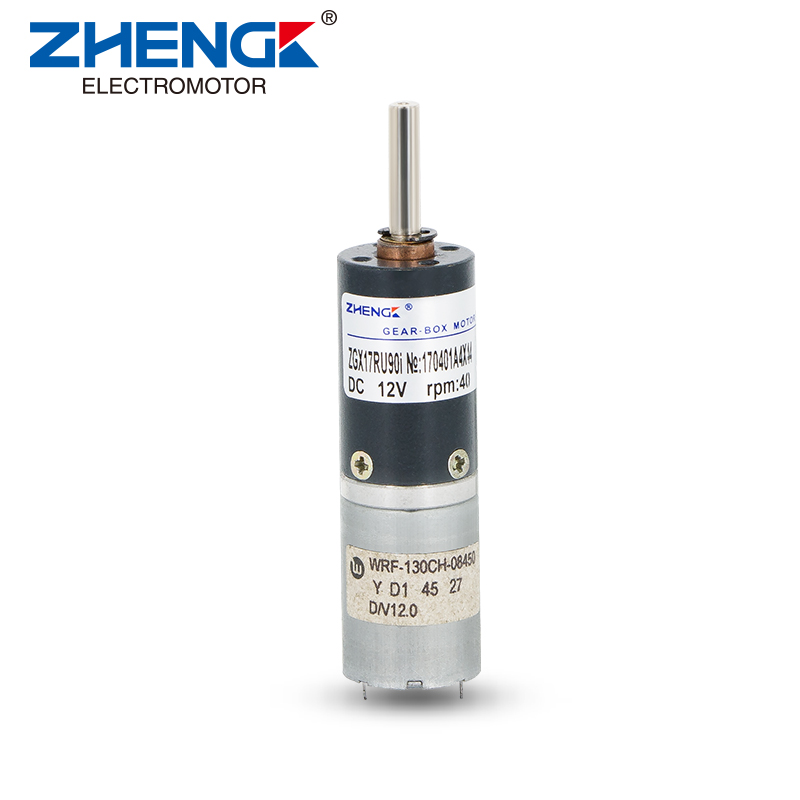

Mechanical factors potentially causing DC motor operational abnormalities include misalignment, load imbalance, bearing wear, shaft damage, and excessive belt tension. Misalignment causes shaft oscillation, generating excessive vibration and noise that can damage the motor over time. Load imbalance causes motor vibration, leading to premature failure of bearings or other components. Bearing wear results in excessive friction and heat generation, ultimately causing motor failure. Shaft damage induces motor vibration and noise, damaging bearings and other parts. Excessive belt tension overloads the motor, causing overheating and failure.

Electrical factors that may cause abnormal operation of DC motors include overvoltage, undervoltage, overcurrent, and electrical noise. Overvoltage causes excessive current to flow through the motor, leading to overheating and motor failure. Undervoltage reduces Motor Speed, resulting in overheating and motor failure. Overcurrent causes motor overheating and winding damage, leading to motor failure. Electrical noise interferes with motor operation and causes it to malfunction.

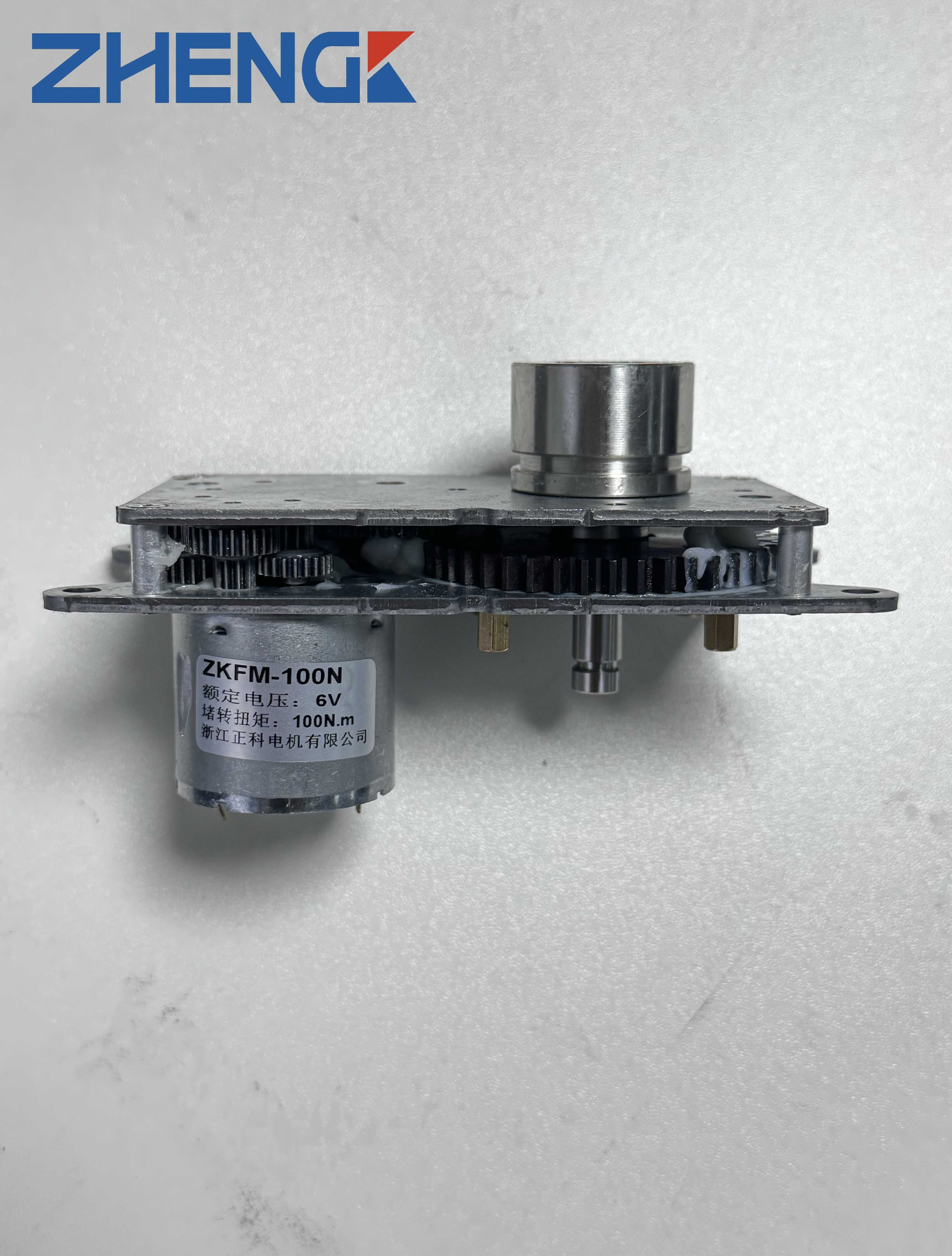

Another factor contributing to abnormal DC motor operation is inadequate maintenance. Regular maintenance is crucial for ensuring smooth motor operation and extending service life. Lack of maintenance allows dust and debris to accumulate inside the motor, leading to overheating and motor failure. Additionally, it causes lubrication failure, increasing friction and wear on motor components.

Numerous causes exist for abnormal DC motor operation, encompassing mechanical and electrical factors, as well as improper maintenance. Identifying and addressing these causes is vital for preventing or mitigating issues and ensuring reliable, efficient DC motor operation. Regular maintenance—such as cleaning and lubrication—helps prevent problems caused by dust and debris buildup. Proper calibration, load balancing, and belt tensioning help prevent mechanical failures. Electrical issues can be resolved by ensuring appropriate voltage and current levels and minimizing electrical noise. By addressing these causes of operational irregularities, DC motors can consistently deliver reliable, efficient power for diverse applications.