Application of Grease in Gearboxes

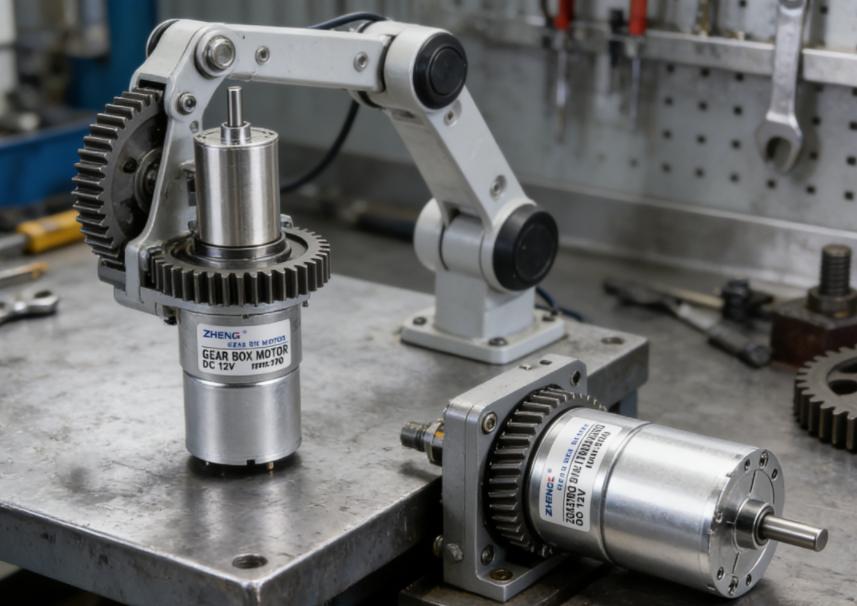

Micro gear motors find extensive applications across telecommunications, smart home systems, automotive, medical, security, and robotics sectors. Within this domain, small-module gear drives are gaining increasing attention and importance in Micro Gear Motors. The grease used in the reduction gearbox plays a crucial supporting role, serving primary functions such as: ① Reducing friction and wear, preventing adhesion; ② Lowering noise levels; ③ Absorbing impact and vibration; ④ Preventing rust and corrosion; ⑤ Dissipating heat, cooling, and expelling contaminants; ⑥ Extending gear meshing life.

The selection of gear materials and lubricating grease in reduction gearboxes is closely interrelated. For gear transmission systems operating under normal conditions, the lubricant must exhibit the following characteristics: ① Appropriate viscosity; ② High load-carrying capacity; ③ Excellent anti-wear properties; ④ Oxidation stability and thermal oxidation stability; ⑤ Anti-emulsification, anti-foaming, rust prevention, and corrosion resistance; ⑥ Good fluidity, low pour point, and safe usage; ⑦ EP (extreme pressure) additives providing wear protection under mixed friction conditions.

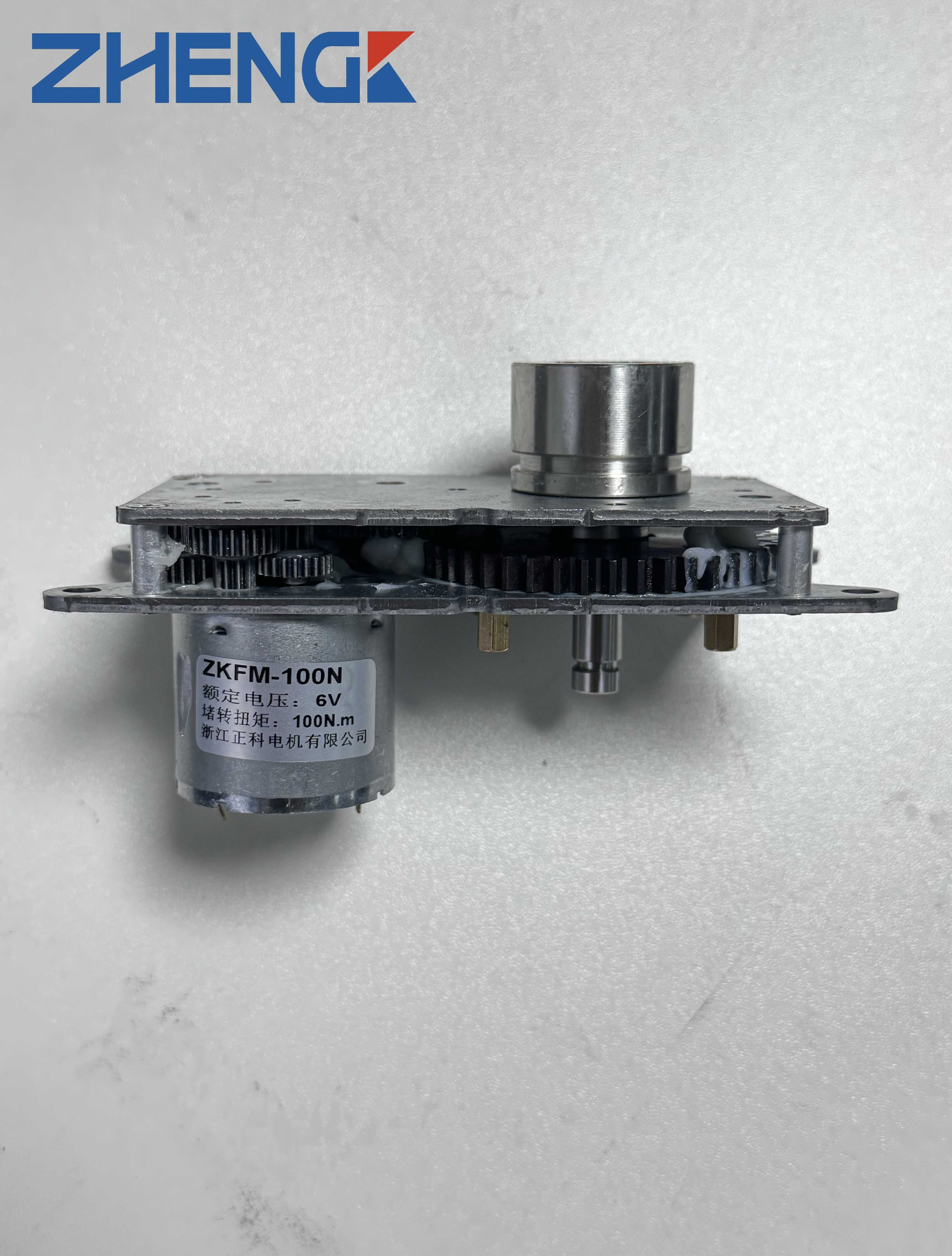

Gear materials in reduction gearboxes typically include metals, powder metallurgy, plastics, and MIM (Metal Injection Molding). Due to material differences, output torque, current, temperature, speed, and noise requirements often vary. Additionally, gearbox structures impose distinct demands on grease properties, leading to the development of greases with specialized characteristics.

Broadly speaking: ① The more compact and smaller the gear reducer structure, the smaller its heat dissipation area. This demands higher extreme pressure performance and better thermal stability from the grease. ② In transmissions with multiple gear pairs meshing, the grease must exhibit anti-foaming properties and high adhesion during operation. ③ Operating temperatures fluctuate with varying torque loads during gear meshing, necessitating excellent viscosity-temperature characteristics and low volatility at both startup and normal operating temperatures; ④ Materials used in gearboxes—such as bearings, oil seals, and diverse gear materials—require greases with superior compatibility and oxidation resistance.

Selection of Grease Viscosity:

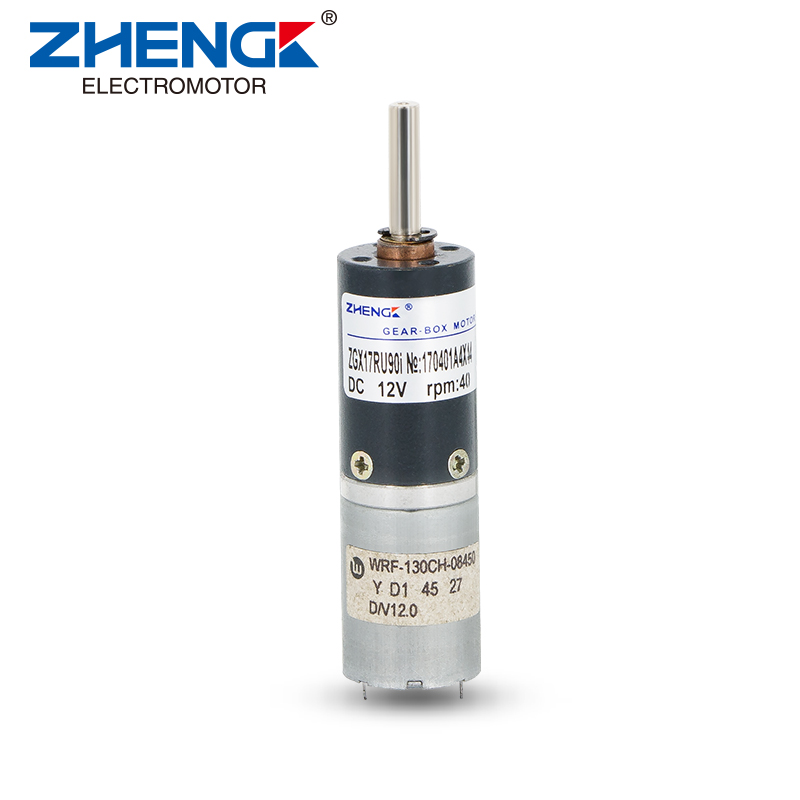

The output performance of a reduction gearbox is closely related to the gear material used and the viscosity of the grease. Typically, gearboxes with higher output torque require metal gears to achieve longer service life or prevent specific failure modes. High-viscosity grease offers superior adhesion, providing better protection and vibration damping for metal components, which effectively reduces gearbox noise. Therefore, high-viscosity grease is generally preferred in such applications. For low-output-torque reduction gearboxes, gears are typically made of plastic. Using high-viscosity grease would significantly increase output current or torque as the gearbox overcomes viscosity-induced resistance, thereby restricting operation. Thus, low-torque or plastic-gear gearboxes usually employ low-viscosity grease. For high-speed gearboxes, where gear rotational speeds are elevated, requirements typically call for lower starting currents or torques. Consequently, low-viscosity grease is generally preferred.

Grease Quantity Selection:

The amount of grease in a reduction gearbox determines factors like gear meshing lifespan and noise levels. Excessive grease increases costs. Different gearbox structures require varying grease quantities:

- Planetary gearboxes typically require filling 50-60% of the gear meshing clearance volume. Parallel-shaft or cross-shaft gearboxes often have more clearance, so grease volume should be selected based on achieving relatively low noise across multiple gear pairs. For Worm Gearboxes and spur gearboxes, filling 60% of the tooth space volume is recommended.