Considerations for Permanent Magnet DC Motor Applications

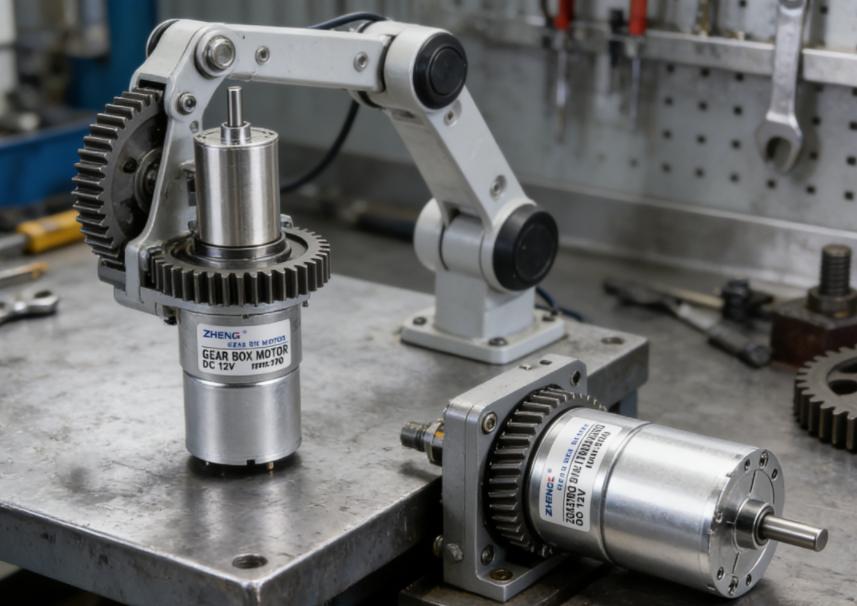

Permanent magnet DC motors can be divided into brushless permanent magnet Dc Motors and brushed permanent magnet DC motors according to the presence or absence of brushes. These motors utilize permanent magnets to generate a magnetic field and are widely used in a variety of portable electronic devices and electrical appliances, such as tape recorders, VCD players, vinyl records, electric massagers, toys, as well as automobiles, motorcycles, hand dryers, electric bicycles, batteries, cars, ships, aviation, machinery and other industries. In addition, they are used in large quantities in high-precision products such as VCRs, copiers, cameras, cell phones, precision machine tools, money counters, and money counting machines.

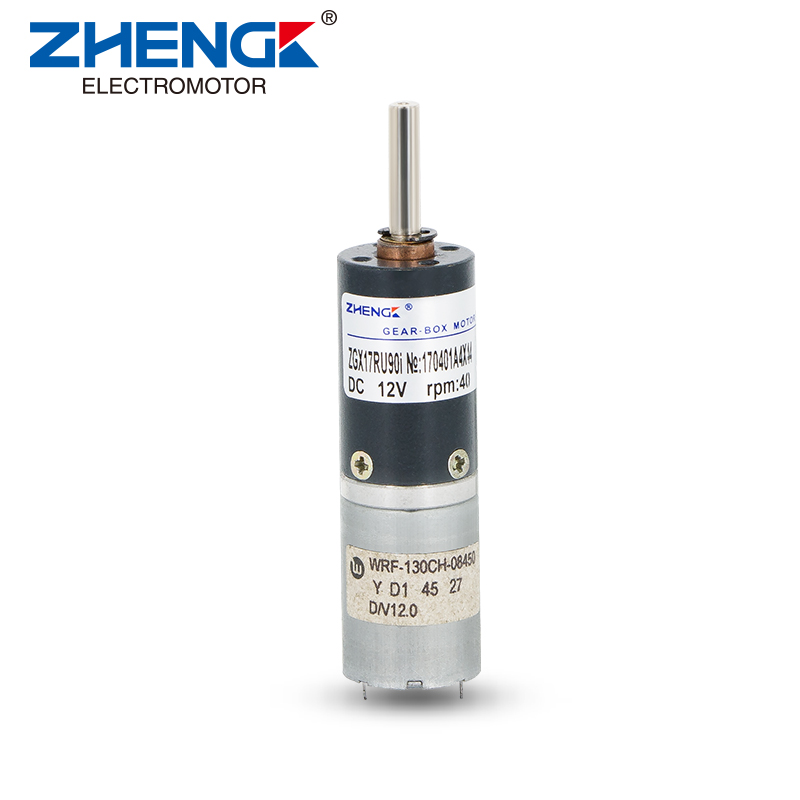

Permanent magnet DC motors utilize one or more permanent magnets to establish a magnetic field. Similar to other-excited DC motors with stable excitation currents, these motors can easily regulate the armature voltage and have the advantages of small size, high efficiency, simple structure, and low copper loss compared to other-excited DC motors. They are the main type of low power DC motors.

Application considerations for permanent magnet DC motors include:

1. Reverse braking operation: Unless explicitly stated otherwise, permanent magnet DC motors should not normally be reverse braked at rated voltage to prevent demagnetization of the permanent magnets. If reverse braking is required, a current limiting resistor should be added to limit excessive current.

2. Quality Inspection:

Check the appearance of the motor for scratches, dents, or flaking coatings.

Check that the rolling shaft rotates smoothly and flexibly with no obvious stalling.

Ensure that the motor is securely connected and check for any energized operation.

Confirm that there is no friction in the motor during operation, paying particular attention to bearing friction. Worn bearings may cause abnormal noise, localized overheating and increased temperature.

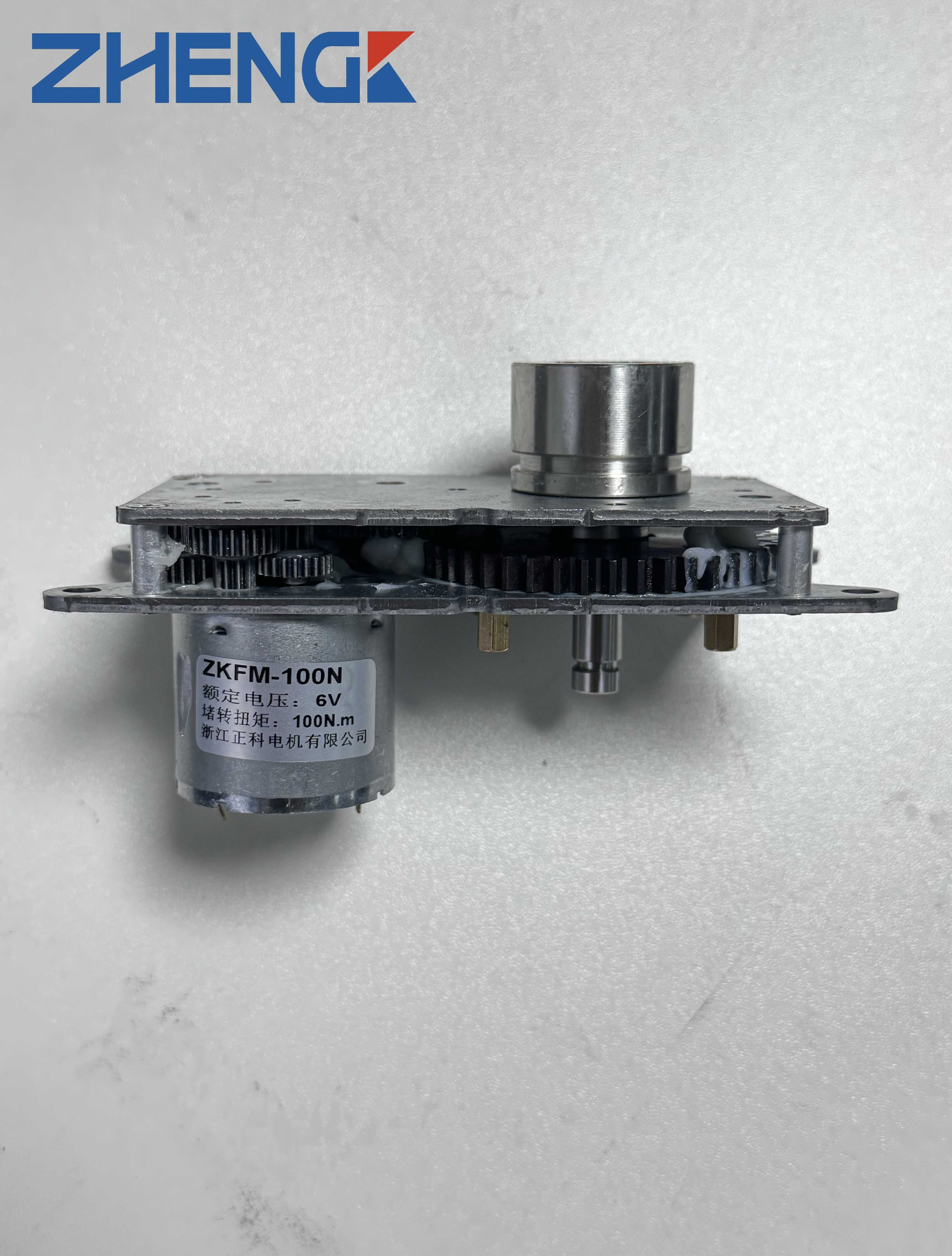

3. Disassembly Precautions:

Pay particular attention to excessive current, temperature changes, and demagnetization caused by opening the magnetic circuit during disassembly. Be sure to maintain the magnetic short circuit of the permanent magnet magnetic circuit during disassembly to prevent self-magnetization after demagnetization.