DC motors and planetary gearboxes used in modern automation

In the evolving world of automation and robotics, the demand for compact, high-efficiency motion systems continues to rise. At the heart of many of these systems lies a powerful combination: DC permanent magnet motorspaired with Planetary Gearboxes. These components provide the torque, control, and durability needed for precision applications in everything from electric locks to advanced robotic arms.

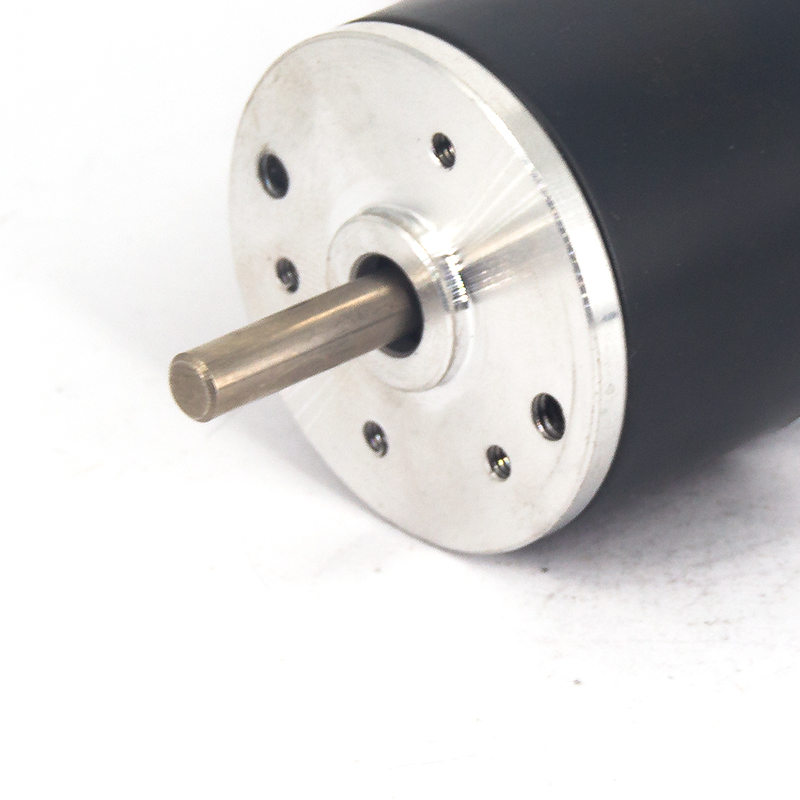

Compact Power: Small Brushless Dc Motors

One of the key advancements in the electric motor industry is the small brushless DC motor. These motors are highly efficient, generate minimal heat, and offer extended service life. Their compact size makes them an ideal choice for space-constrained systems like smart door locks and medical automation tools. With smoother operation and lower noise compared to brushed alternatives, brushless DC motors are rapidly becoming the preferred option for modern mechatronics.

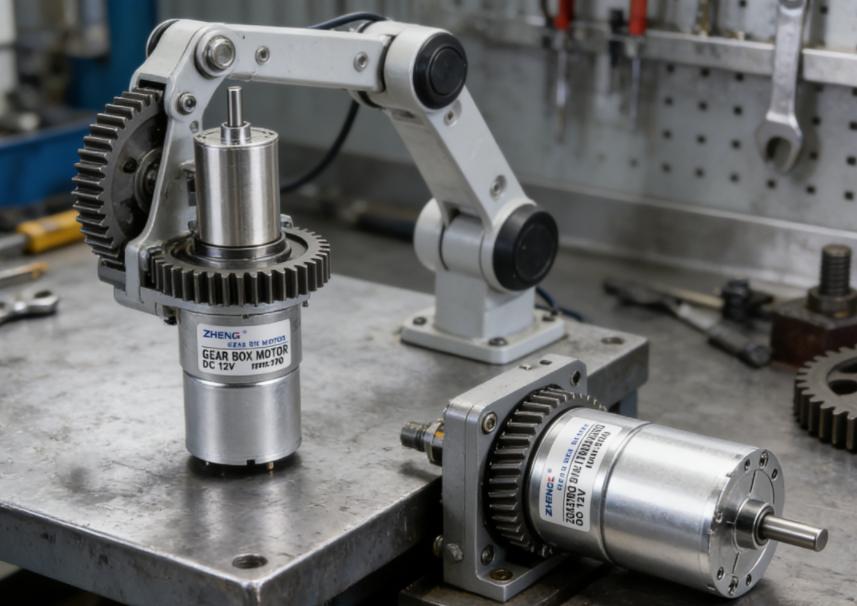

Precision Control with 36mm Planetary Gearboxes

When engineers need high torque at low RPMs, particularly in robotic applications, the 36mm planetary gearbox becomes a go-to solution. These gearboxes are specifically designed to handle significant torque loads in a compact footprint, making them ideal for robot joints, electric actuators, and automated equipment. Their multistage design allows for greater gear reduction ratios, improving torque output while maintaining smooth and accurate motion.

High Torque, Low RPM Motors for Robotics

High torque, low RPM motors are essential for robots that require powerful and controlled movements. Whether it's a robotic arm lifting heavy payloads or a mobile robot navigating uneven terrain, torque matters. Paired with planetary gearboxes, these motors deliver the mechanical advantage needed for stability, strength, and responsiveness in dynamic environments.

Seamless Integration: Motor Automation Solutions

We specialize in delivering complete motor automation solutions. From electric motor planetary gearbox assemblies to customized DC motor planetary gearbox configurations, we support OEMs across industries like smart home devices, vending systems, and healthcare equipment. Our engineering team ensures that each solution is optimized for efficiency, durability, and seamless integration into your application.

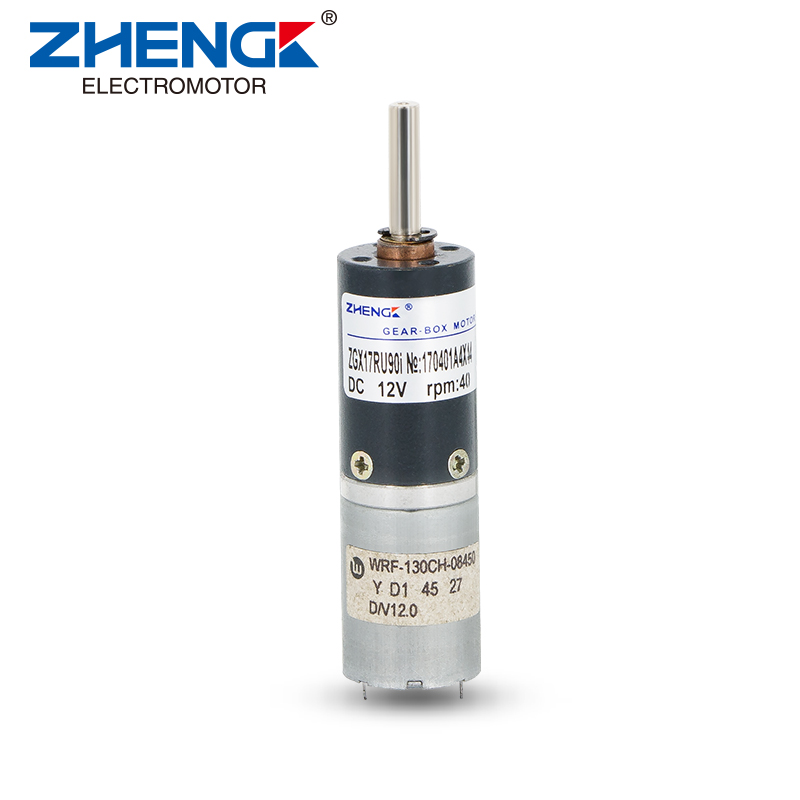

Planetary Gearbox for Brushless Motor Applications

Integrating a planetary gearbox for brushless motor setups enhances both torque and positional accuracy. This pairing is commonly used in robotic grippers, servocontrolled systems, and smart actuators. The gearboxes absorb mechanical stress, protect the motor, and allow for finer control—key factors in industrial automation and precision engineering.

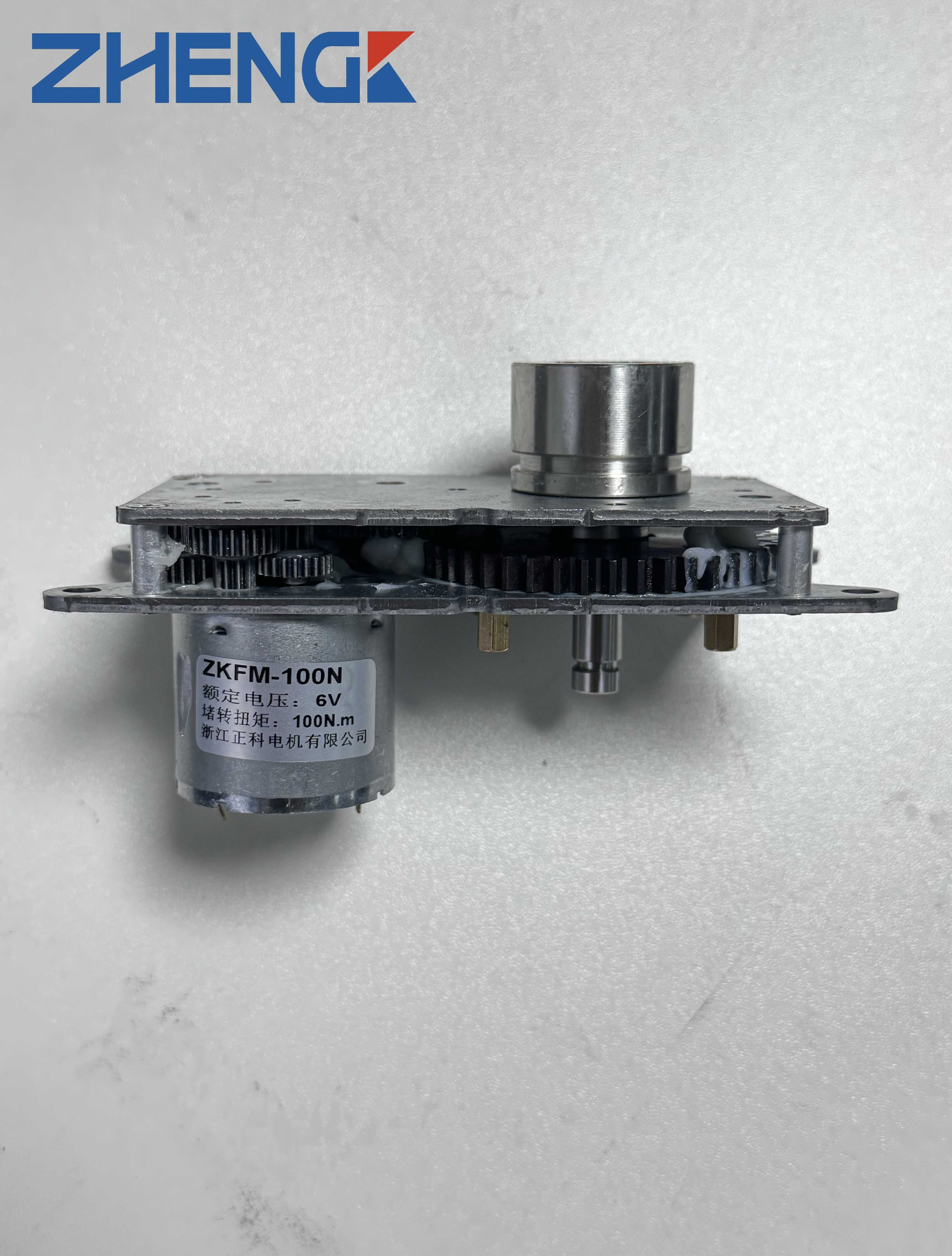

Secure and Reliable: Gear Motors for Electric Locks

Security applications, such as electric locks, benefit greatly from high torque reducer gear motors. These compact units offer strong holding force, reliability in varied temperatures, and quiet operation—critical features for door automation in offices, hotels, and residential buildings. With our planetary gear motors, manufacturers can ensure longlasting performance and user satisfaction.

In today's fast-moving tech landscape, selecting the right motor and gearbox combination is critical to system success. Our range of DC permanent magnet motors, brushless DC motors, and planetary gearboxes is engineered to meet the exacting standards of automation, robotics, and security.