Why DC Motors Lead in Precision and Performance

In today's rapid development of industrial automation, intelligent equipment and new energy technology, Dc Motor, as a classic power unit, has always occupied an important position by virtue of its unique performance advantages. From household appliances to aerospace equipment, from precision medical instruments to heavy industrial machinery,DC motors are everywhere. In this article, we will analyze the core principle, outstanding advantages, widely used areas and scientific maintenance methods of DC motors, which will help you fully understand the source of this efficient power.

The core advantages of DC motor: why choose it?

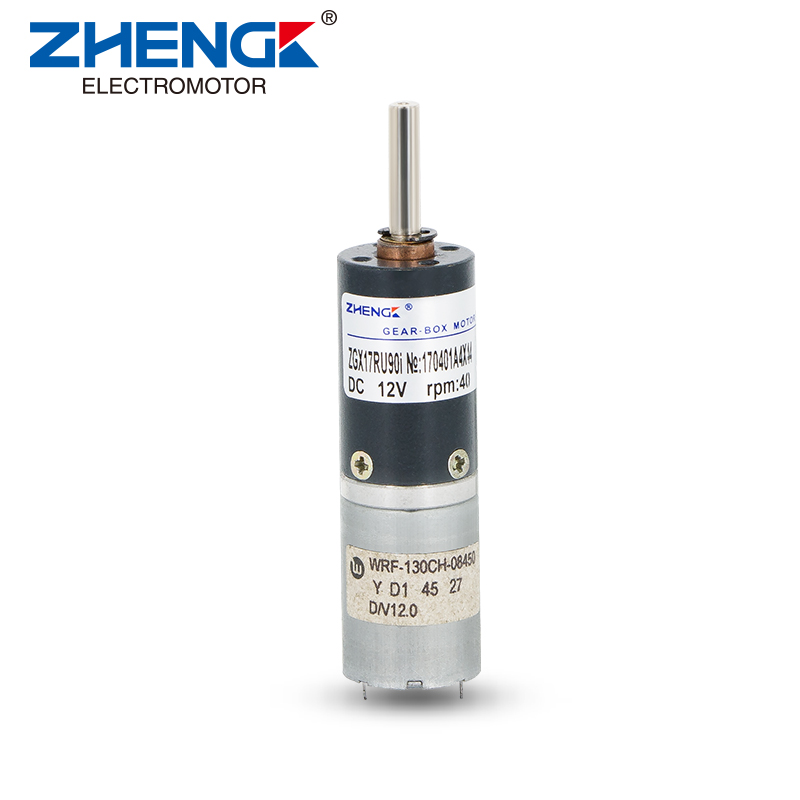

1. Accurate speed regulation performance

DC motor can realize stepless speed regulation by adjusting the input voltage or magnetic field current, and the speed regulation range is wide (up to 1:10 or even higher). This feature makes it irreplaceable in scenarios where precise speed control is required (e.g. machine tools, robots).

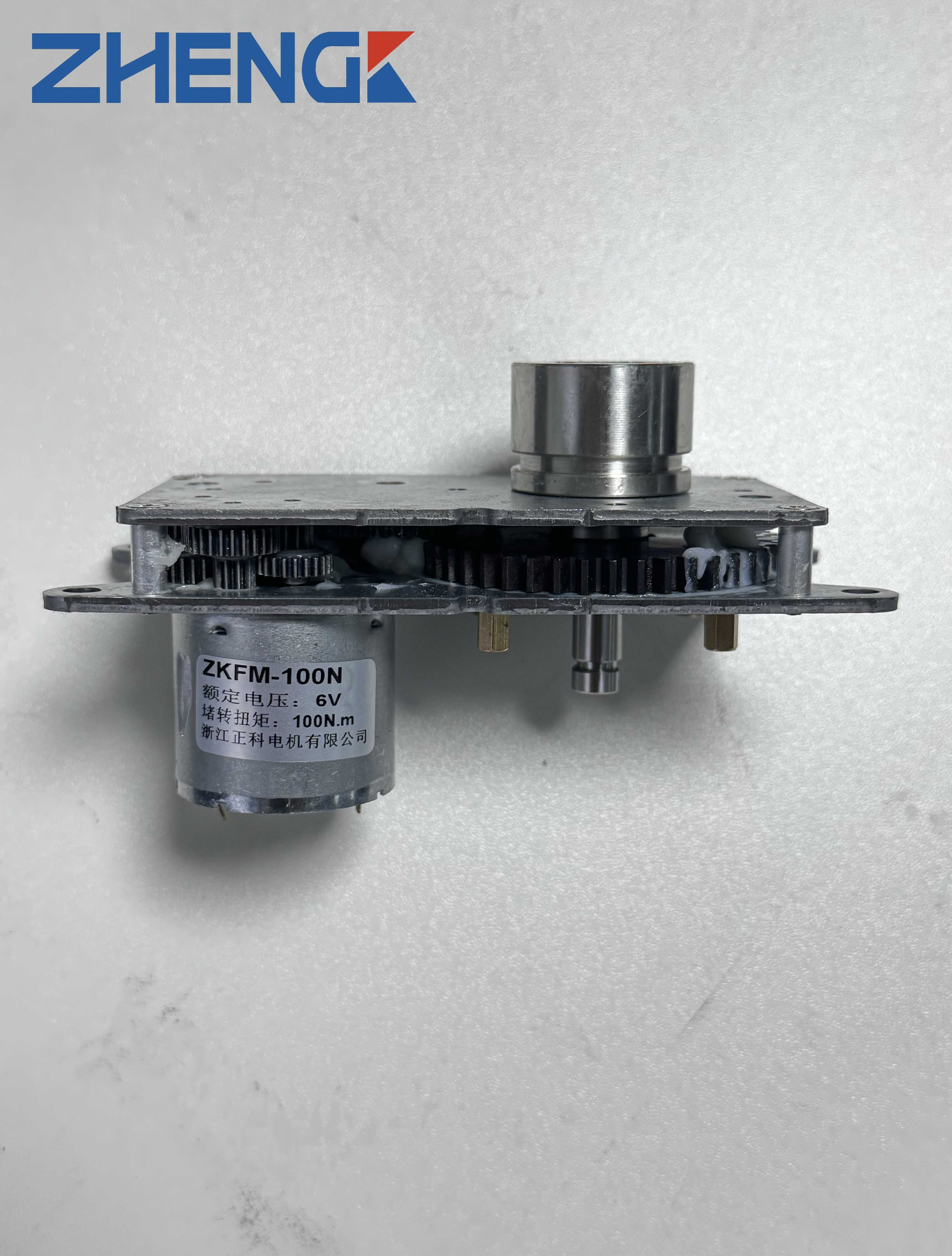

2. High starting torque

DC motors can output the maximum torque (about 2-5 times of the rated torque) at the moment of starting, which is especially suitable for heavy-duty starting applications, such as electric forklifts, cranes and so on.

3. Fast response speed

Electromagnetic inertia is small, the delay between the control signal and the mechanical action is very short, suitable for closed-loop control systems that require fast response.

4. Simple structure, easy maintenance

Compared with AC frequency conversion motor, traditional DC motor can realize speed regulation without complex frequency converter, and the threshold of disassembly and maintenance is low.

5. Wide compatibility

Can be directly powered by the battery (such as electric vehicles), can also be used through the rectifier AC power supply, strong adaptability.

Application areas of DC motors: full coverage from industry to life

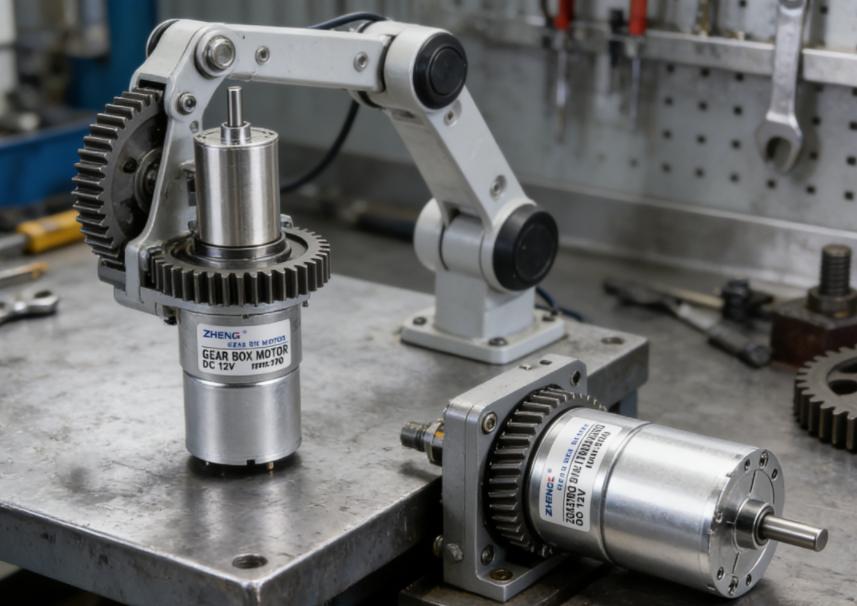

1. Industrial automation

- Conveyor belt drives in CNC machine tools and automated production lines

- Precise positioning and speed control of packaging machines

- Robot joint drive (with encoder to realize closed-loop control)

2. Transportation

- Power motors for electric vehicles (mainly permanent magnet DC motors)

- Traction auxiliary system for rail transportation

- Ship rudder control

3. Consumer electronics and home appliances

- Power tools (electric drill, angle grinder)

- Household appliances (vacuum cleaners, electric curtains)

- Drones, model cars and other recreational equipment

4. Medical and precision equipment

- Lifting drives for medical beds

- Laboratory centrifuges, microscope stage adjustment

- Micro-motor control of prosthetic joints

5. New energy and energy storage

- Solar tracking system azimuth adjustment

- Pitch control for wind turbines

Scientific maintenance of DC motors: the key to prolonging their service life

In order to guarantee the efficient operation and prolong the service life of DC motors, the following maintenance principles should be followed:

1. Regular cleaning and dustproofing

- Use compressed air to remove carbon powder accumulation on the surface of brushes and commutator (once every 500 working hours).

- Avoid metal dust and oil from entering the motor, and install protective cover if necessary.

2. Brush and commutator maintenance

- Check the wear of brushes and replace them when the length is less than 1/3 of the original size (recommended to be checked every 2000 hours)

- Use fine sandpaper to polish the oxidized layer of the commutator to ensure that the contact surface is smooth and free of dents.

3. Bearing lubrication management

- Use high-temperature lithium grease and replenish the grease every half a year.

- Monitor the operation noise, abnormal vibration or noise may indicate bearing damage.

4. Winding insulation inspection

- Use megohmmeter to regularly measure the insulation resistance of the winding to ground (should be > 1MΩ)

- Humid environment need to add moisture-proof coating or use explosion-proof motor.

5. Operating environment control

- Operating temperature should not exceed 40℃, avoid overload operation resulting in high temperature rise.

- Avoid long-term use in corrosive gas environment.

DC motors have been developed for centuries, and their core value has always been to transform electrical energy into precise, reliable and controllable mechanical power. Whether in traditional industrial scenarios or new technology fields, it continues to unleash innovative potential. Choosing the right DC motor and implementing scientific maintenance will inject lasting power into your equipment, helping to enhance both efficiency and value.