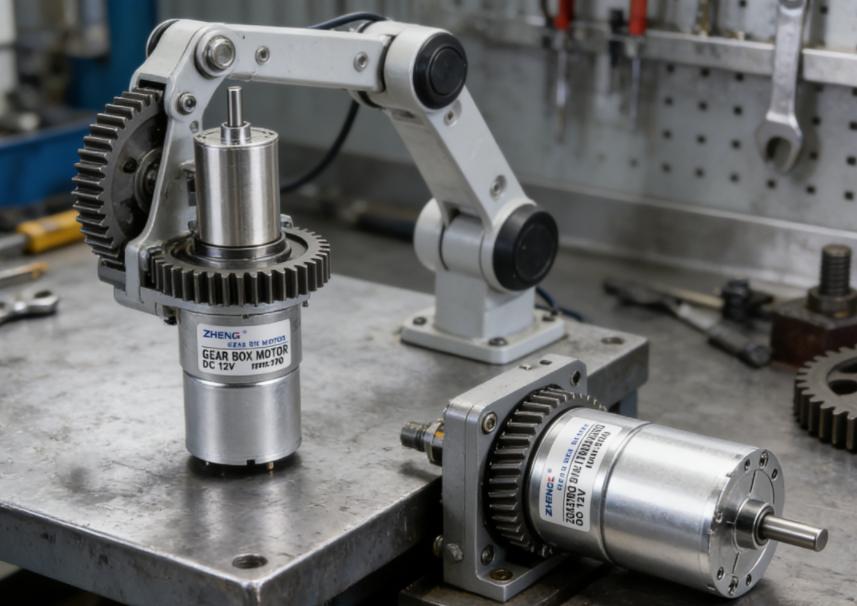

How do micro gear motors increase torque for motorized window treatments?

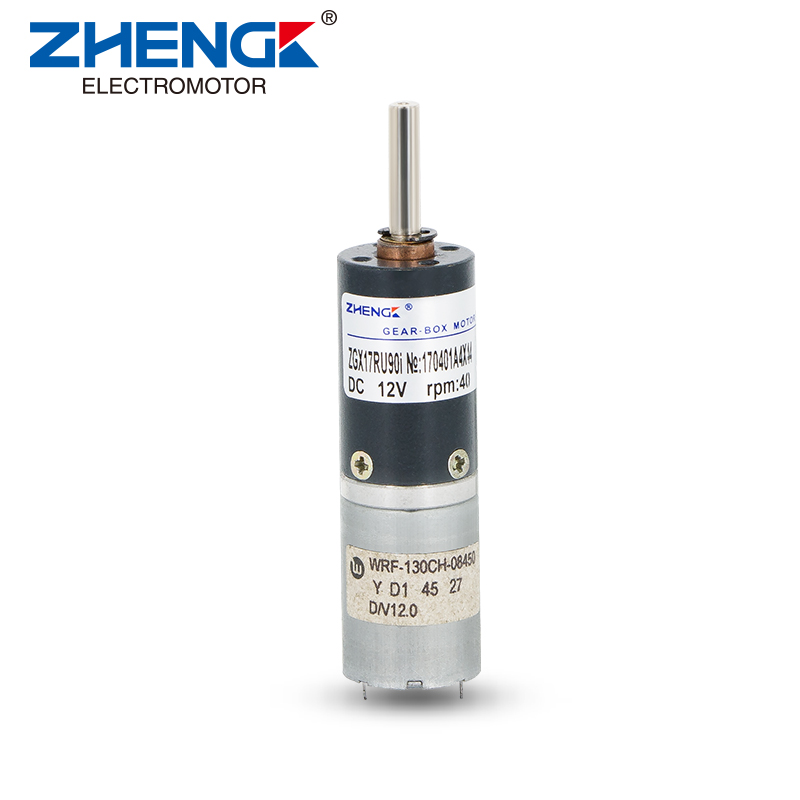

The torque size of the gearbox is determined by the power and rotational speed, the rated output torque is determined by the rated transferred power and output rotational speed, the actual output torque is determined by the actual transferred power load size and actual output rotational speed.

The output torque of the micro gear motor will increase while the rotational speed decreases. The torque output ratio is the output power of the Micro Motor multiplied by the reduction ratio, and the load inertia decreases when decelerating, and the amount of inertia reduction is the square of the reduction ratio.

Micro gear motors serve other purposes besides reducing the output speed:

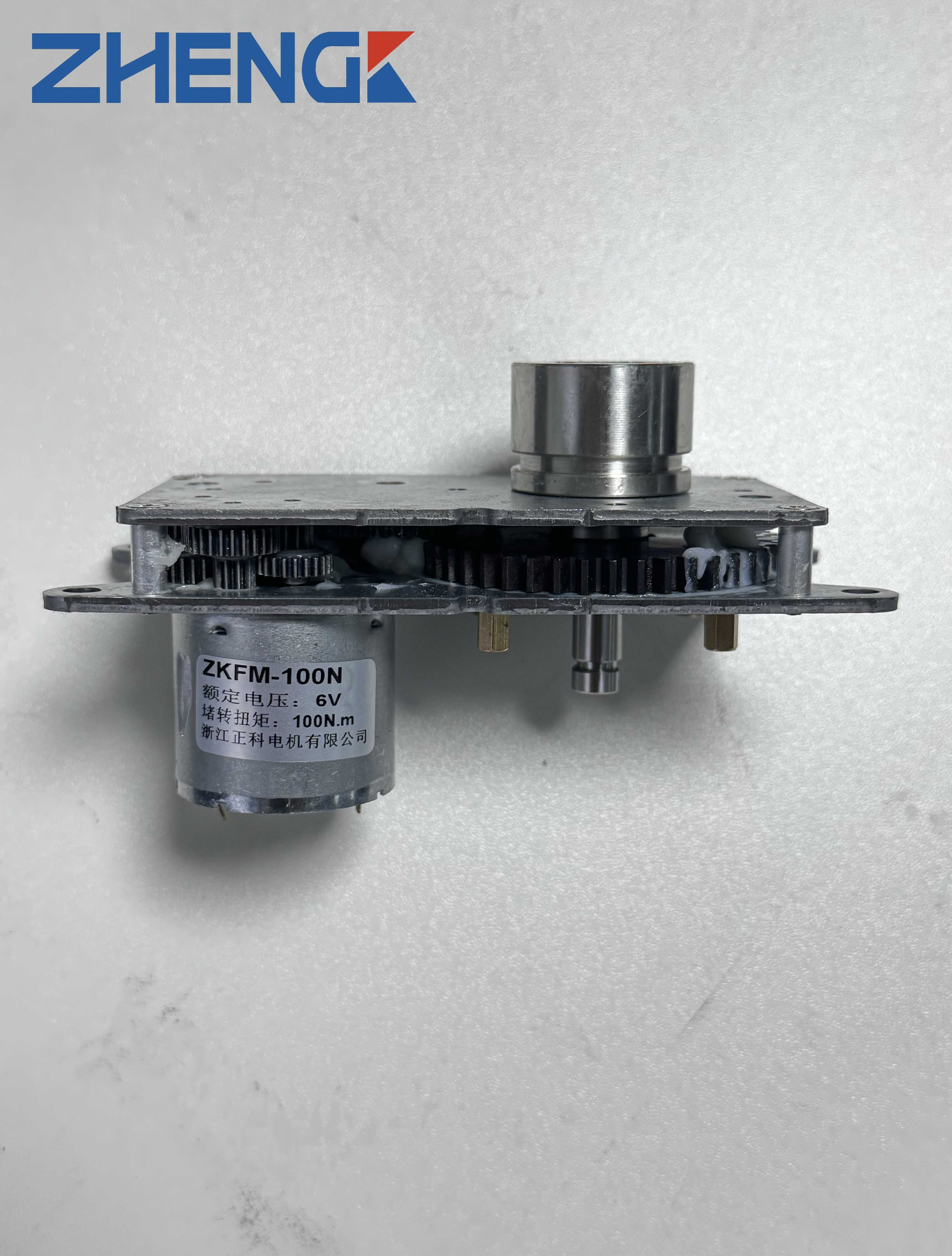

The gearbox serves to protect the micromotor during transmission. In case of overload, only the value of the overload minus the reduction ratio is transmitted to the micromotor. At very high overloads, the gear reducer can be damaged. The motor can also be damaged if the gear reducer covers the motor itself.

When the gearbox is directly connected to the load at low speed, the current of the micromotor increases a lot in order to meet the output torque, so the heat dissipation and insulation requirements of the micromotor are higher, and the use of a gearbox motor reduces the impact of such problems.