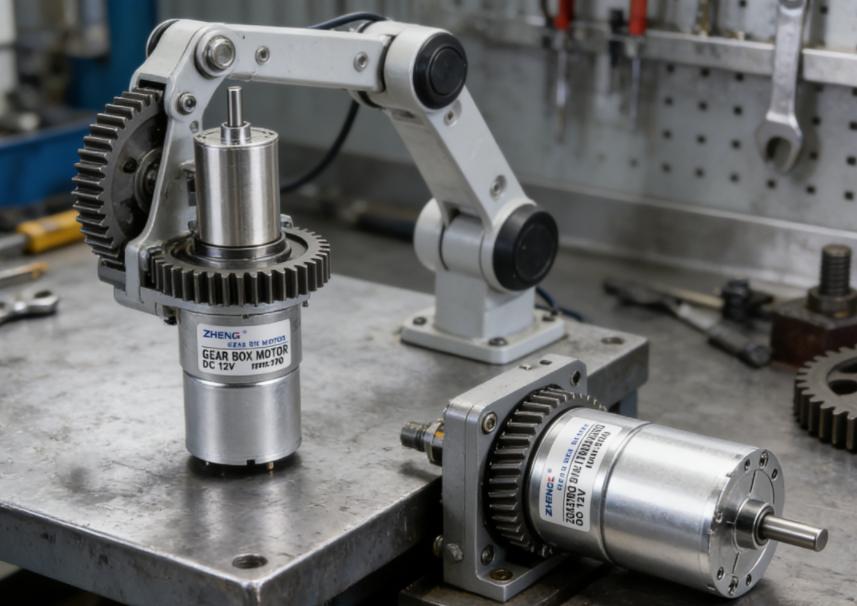

Micro Motor Manufacturing Process and Advantages

Micro motors are widely used in electronic devices, home appliances, medical equipment, and other fields. Their production processes are complex and precise, with each step directly impacting the motor's performance and quality. The following provides a detailed analysis of the production process for Micro Motors and potential optimization directions:

1. The selection and preparation of high-quality raw materials form the foundation of production and directly affect product quality.

Wires: High-conductivity, heat-resistant copper or aluminum wires are used, with an insulating layer on the surface to ensure electrical performance.

Core materials: Commonly used are silicon steel sheets or low-loss, high-permeability soft magnetic materials.

Insulation materials: Insulation grades (e.g., F-class or H-class) are selected based on the operating environment.

Optimization: Introduce an automated raw material inspection system to enhance consistency and reliability.

2. Insulation is critical for the safe operation of motors.

Insulation coating: Coils are immersed in insulation varnish to provide comprehensive protection.

Drying and curing: High-temperature ovens are used to cure the varnish, enhancing voltage resistance and impact resistance.

Optimization: Adopt vacuum impregnation technology to ensure complete penetration of the varnish.

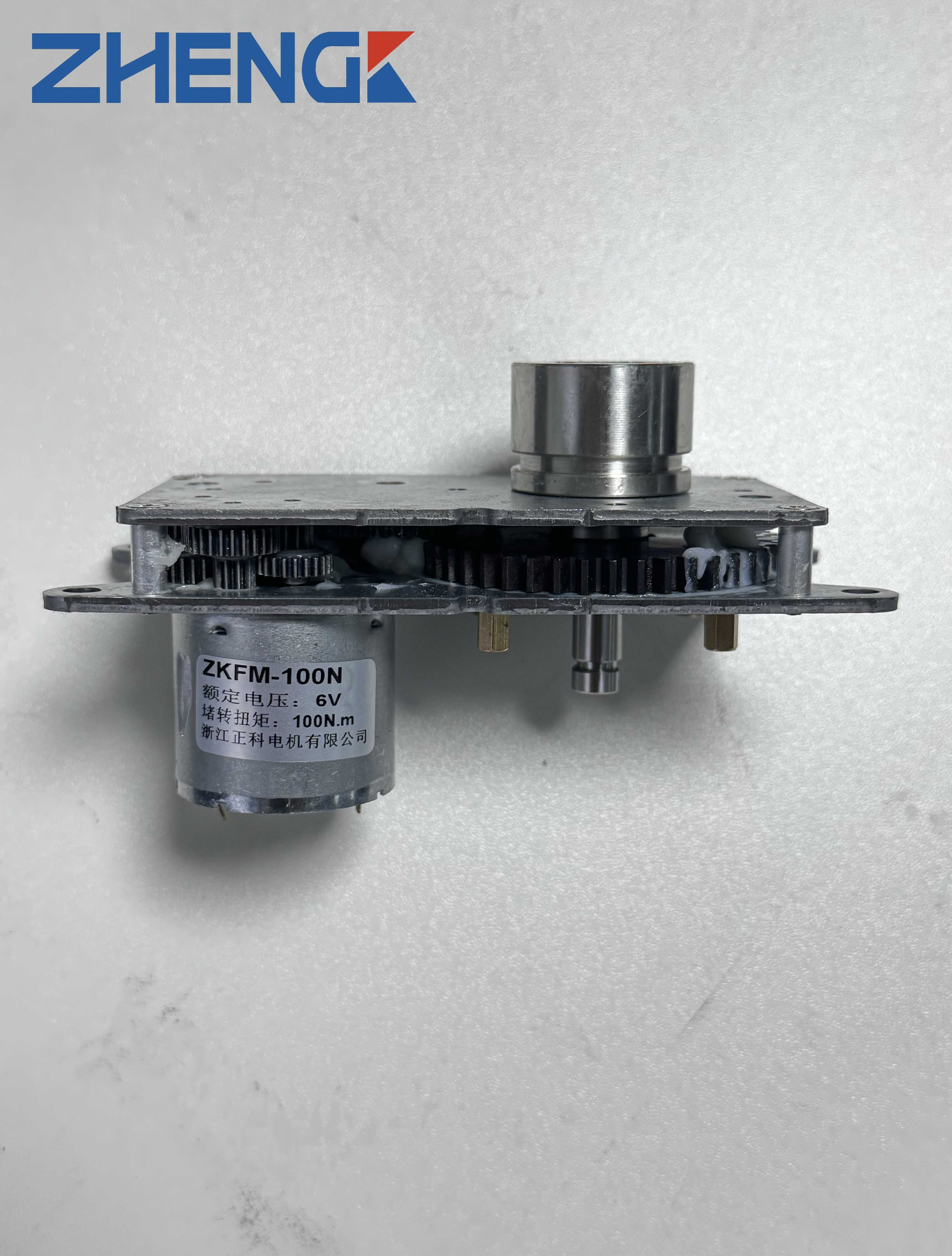

3. Components are precisely assembled to ensure mechanical strength and electrical connections.

Welding: Ensure secure connections between wires and terminals.

Component assembly: Includes installation of the stator, rotor, and bearings, ensuring concentricity.

Optimization: Introduce automated welding and assembly technology to reduce human error and improve efficiency.

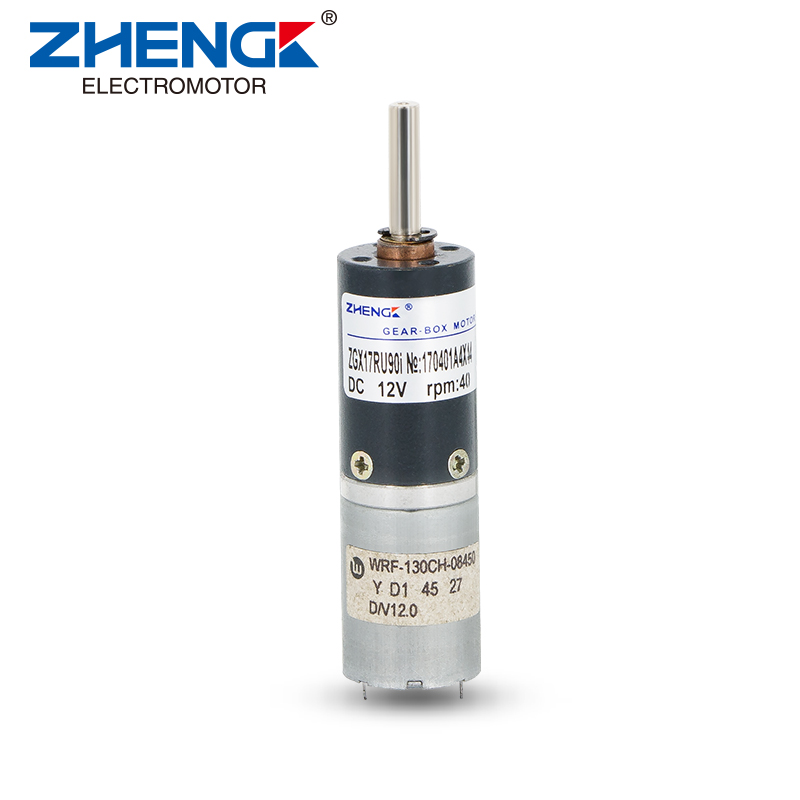

4. The finished product undergoes rigorous performance testing and debugging.

Electrical performance testing: Includes output power, efficiency, and speed testing.

Environmental adaptability testing: Ensures stability under extreme conditions such as temperature and humidity.

Optimization: Deploys an intelligent testing platform to achieve automated detection and data analysis.

5. The final product is cleaned, labeled, and packaged for storage and transportation.

Protective packaging: Ensures that the product remains intact during transportation.

Labeling: Includes product model, parameters, and batch information for traceability.

Optimization: Combining automated packaging lines with RFID technology to achieve better traceability and inventory management.

6. Strict quality control is implemented throughout the entire production process.

Incoming material inspection: Ensuring raw materials meet standards.

Process monitoring: Real-time monitoring of critical production stages to reduce defect rates.

Final product inspection: Ensures each batch of products meets customer specifications.

Optimization: Implement Total Quality Management (TQM) and Statistical Process Control (SPC) to enhance product quality and production stability.

Technological Trends

Smart Manufacturing: Utilize IoT and big data analysis for intelligent production management.

Green Manufacturing: Use eco-friendly materials and energy-efficient processes to reduce carbon emissions.

Modular Design: Enhance product flexibility and maintainability.