Tips for Using DC Geared Motors

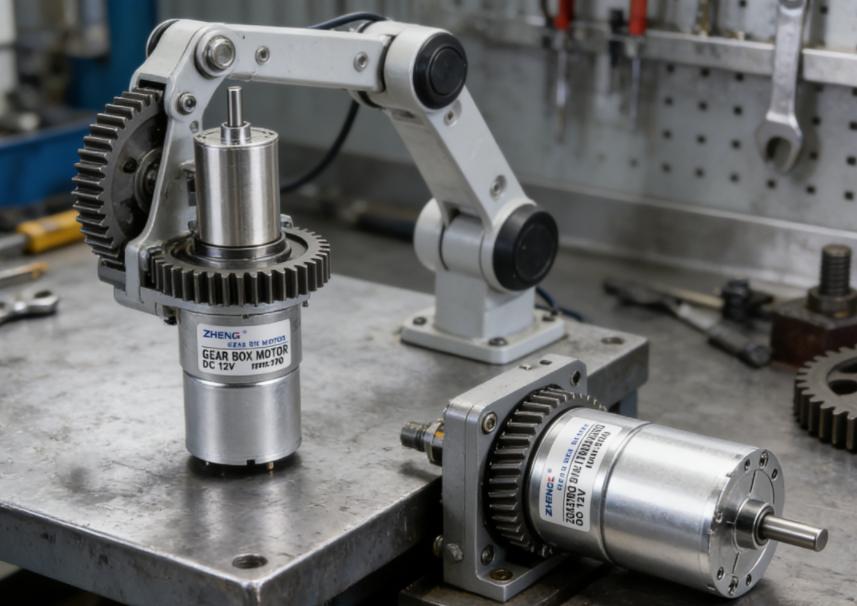

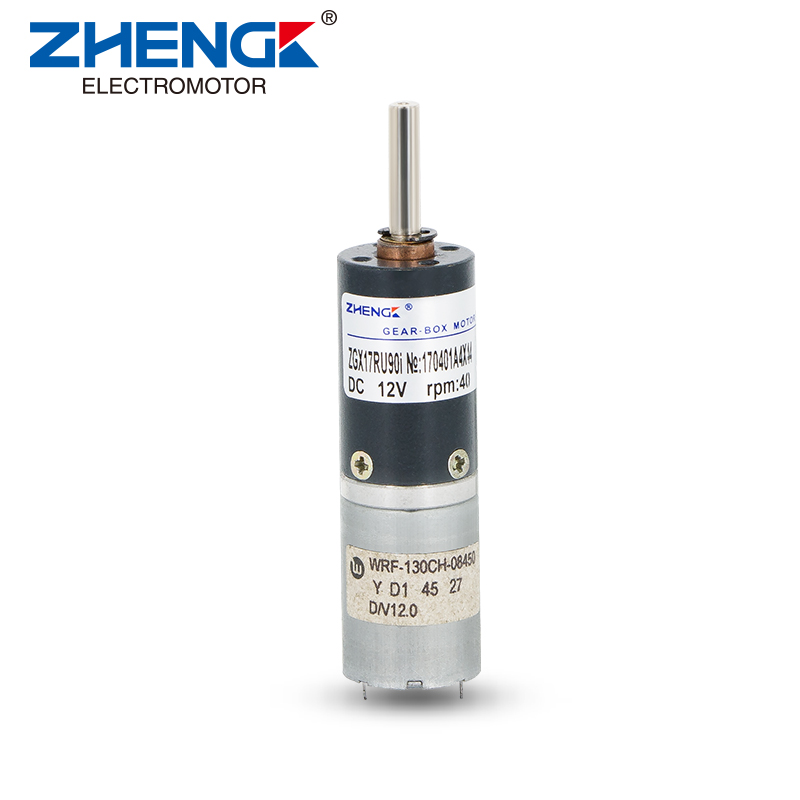

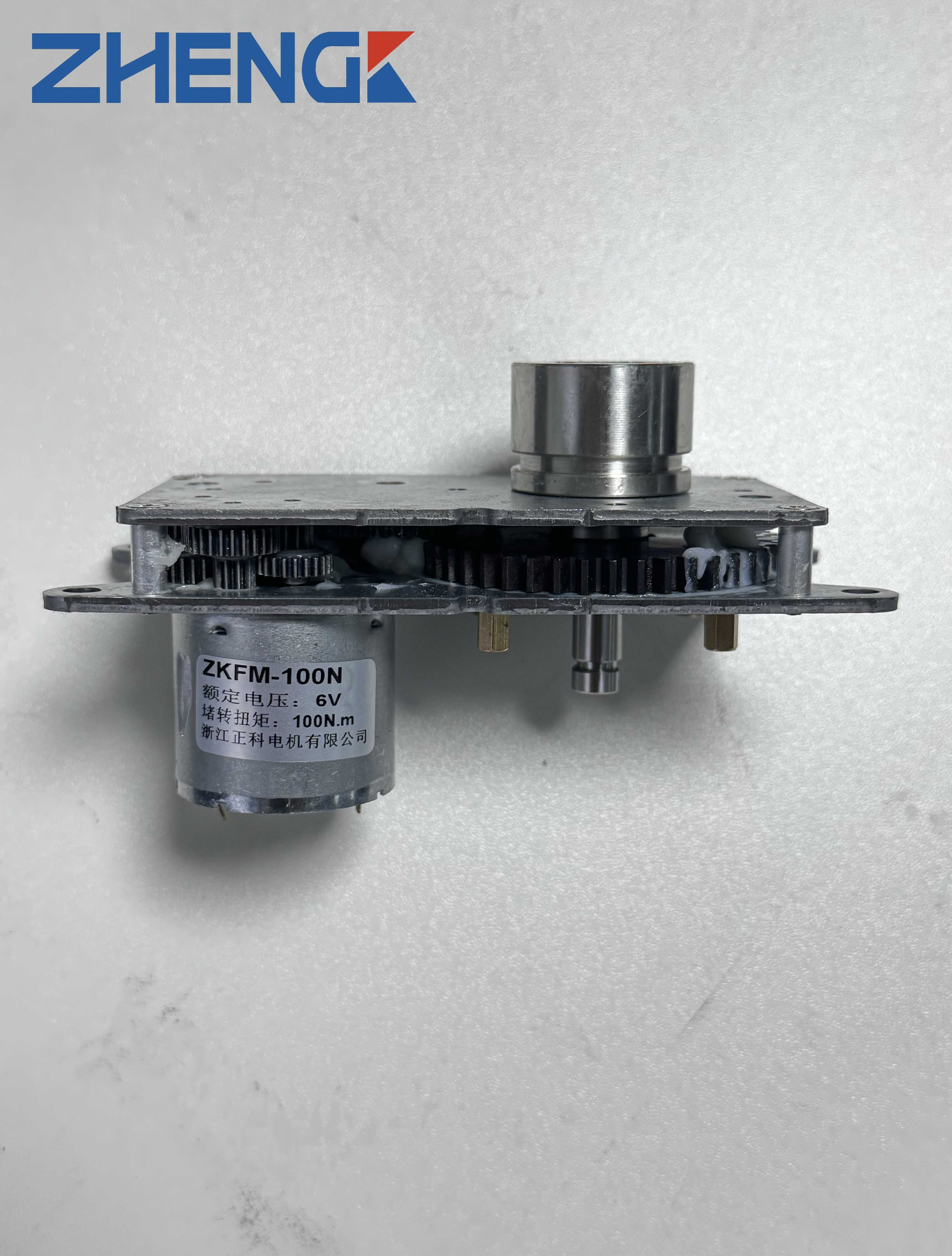

When using DC Gear Motors, numerous factors must be considered, with the most common being their application scope, primarily in the machinery manufacturing industry. As industrial sectors develop and expand, the application range of DC gear motors has entered a new phase. Compared to standard DC motors, DC gear motors incorporate a gearbox, adding a reduction mechanism that precisely adjusts rotational speed within a specific range.

So, what are the specific techniques for using DC gear motors?

First, align the motor's centerline with the center point before startup. This practice extends the motor's operational lifespan.

Adjust the stability of the motor base and ensure proper lubrication to prevent excessive vibration and noise. Noticeable noise or vibration may indicate gear damage, necessitating immediate maintenance and reinforcement of safety devices.

Avoid striking the motor's output shaft with sharp objects, as this can damage internal components.

When operating the DC gear motor, avoid proximity to the motor's working area unless performing practical operations like removing vent plugs or oil plugs. Before each use, thoroughly inspect the motor's condition. Do not operate if any components are loose or lack lubrication.

These are key techniques for using DC gear motors. By adhering to specific operational procedures and standards, we can prevent minor issues, extend mechanical equipment lifespan, and enhance motor operational efficiency.