Understanding DC Motors and Their Applications

In modern engineering, the electric power motoris one of the most essential components powering automation, robotics, and daily-use devices. Among various Motor Types, the DC motor stands out for its simplicity, efficiency, and precise control. Whether it’s a motor DC 500W used in industrial equipment or a small DC fan motor that cools compact electronic systems, DC motors provide reliable and adjustable mechanical power.

Basic Structure and Function

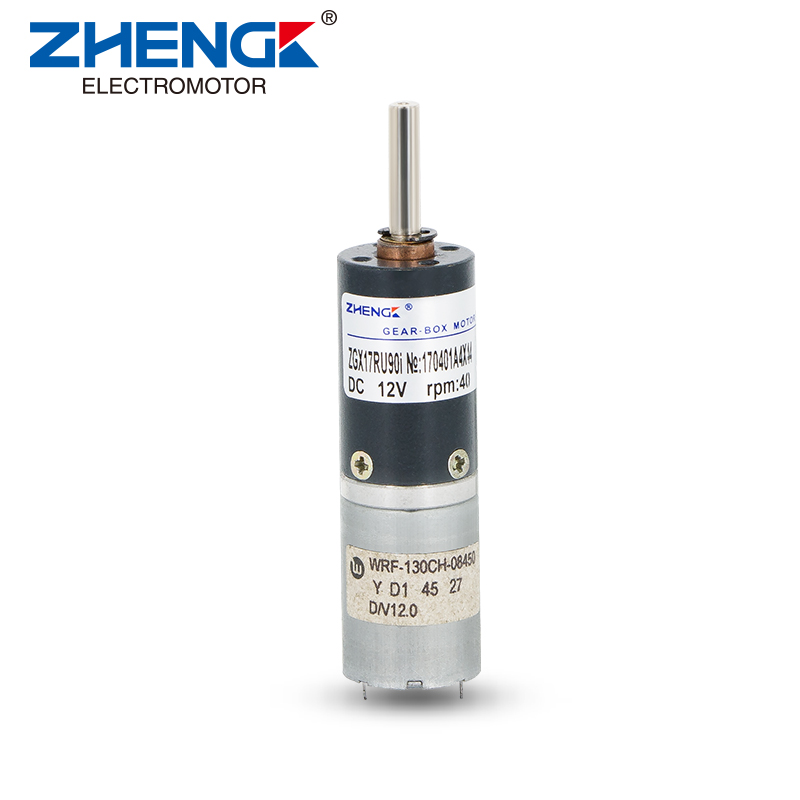

A DC motor converts electrical energy into mechanical motion using direct current. The key components include the rotor, stator, shaft, and carbon brush in the motor. In a carbon brush DC motor, electric current flows through the brushes and commutator to generate motion in the DC motor rotor. This simple yet effective design allows precise control of DC Motor Speed, torque, and direction.

Brushed vs. Brushless Design

Traditional carbon brush motor DC types are widely used due to their cost-effectiveness and ease of control. However, modern BLDC gear motor designs eliminate mechanical brushes, reducing wear and maintenance. The torque of the BLDC motor is smoother and more consistent, offering higher efficiency and longer lifespan — ideal for applications like drones, electric bicycles, and robotics.

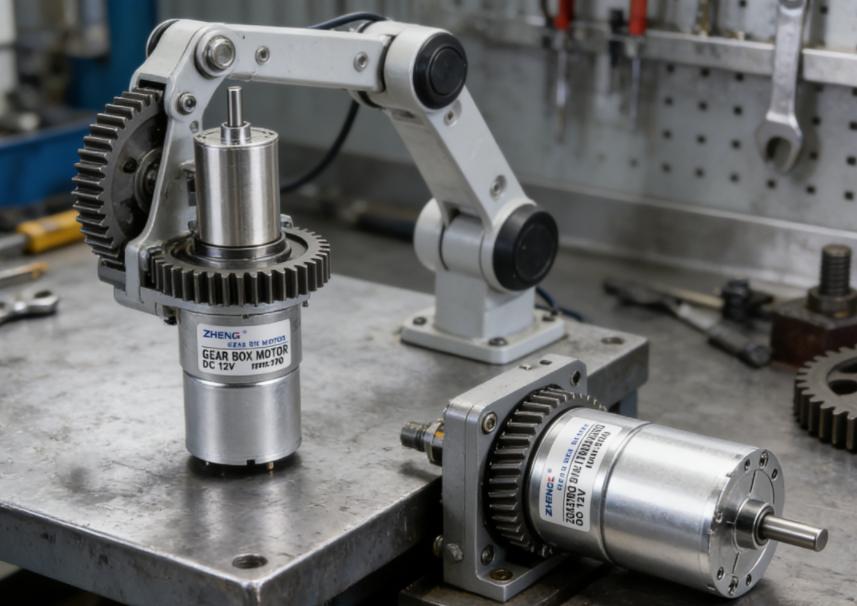

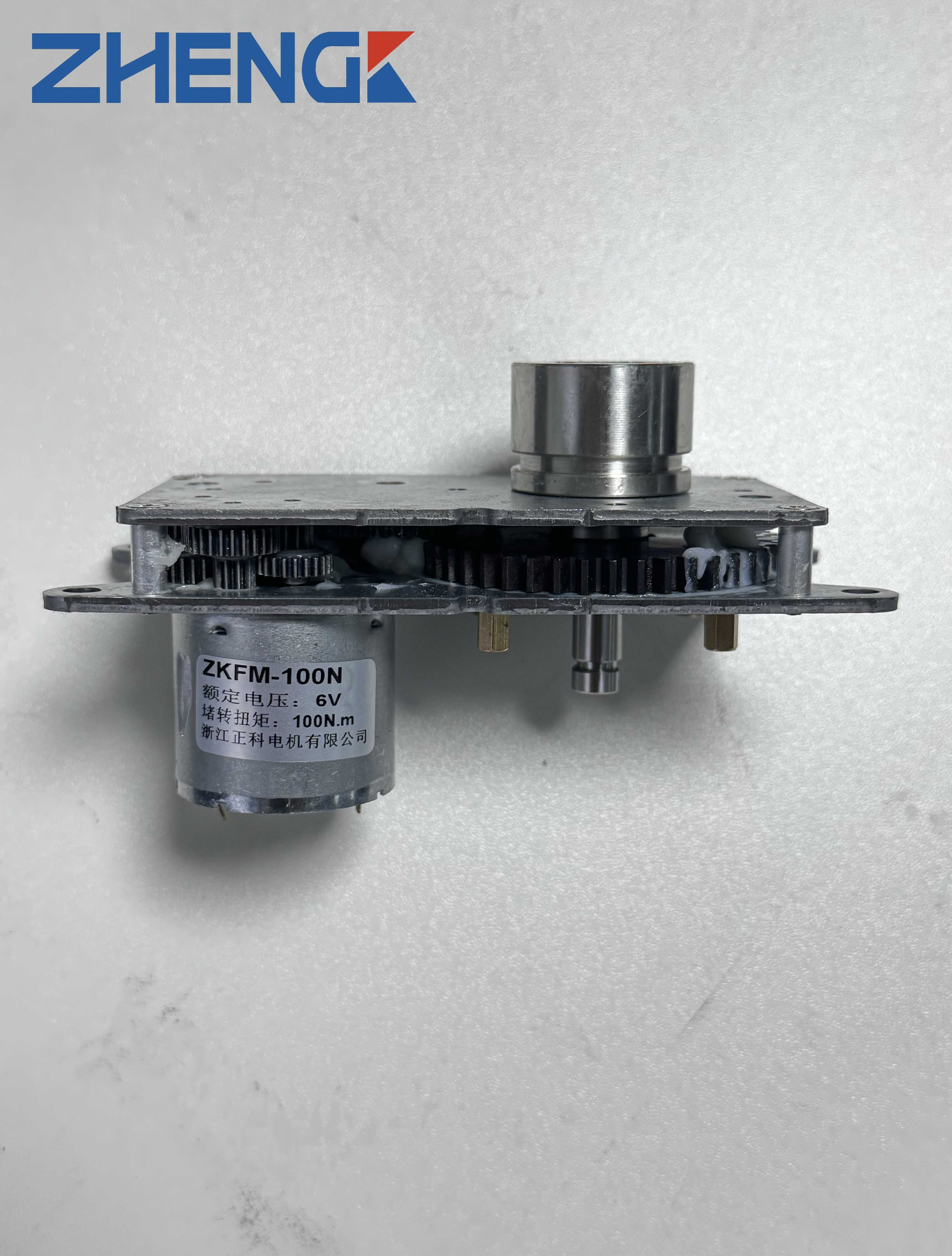

Gear Motors and Torque Transmission

When applications require greater torque at lower speeds, engineers often choose a gear motor type. By combining gears with a motor, a motor of small size can deliver increased output torque while maintaining compact dimensions. This makes DC speed motor systems suitable for automation, actuators, and robotic movement control, where space and accuracy are equally important.

Performance and Voltage Selection

The voltage of a DC motor determines its performance range. For instance, a 6V DC motor is commonly used in toys and small gadgets, offering moderate speed and torque. Meanwhile, a motor DC 500W provides much higher capacity (motor capacity) for industrial tools, conveyors, and electric scooters. Selecting the right voltage and DC motor shaft dimensions ensures proper integration and long-term reliability.

Applications Across Industries

The versatility of DC motors makes them suitable for countless motor applications — from robot motor driver systems and small DC motor fan units to home appliances, automotive devices, and industrial automation. In robotics, for example, DC motors enable precise motion control and stable operation. In cooling systems, small DC fan motors maintain efficient air circulation while consuming minimal energy.

Advantages of DC Motors

The DC motor advantages are numerous: high starting torque, simple speed control, and compatibility with battery-powered systems. Their responsiveness, reliability, and scalability make them indispensable in modern technology. Whether in miniature designs or high-power industrial settings, DC motors continue to drive innovation, efficiency, and performance across multiple sectors.