What should you pay attention to when starting a DC motor?

DC motorsare widely used in industrial equipment, transportation, medical equipment, and other fields due to their simple structure, superior speed regulation performance, and large starting torque. However, the motor startup phase is a high-incidence period for failures. Improper operation may cause winding burnout, accelerated brush wear, and even equipment damage. This article will systematically explain the key precautions for starting a Dc Motor from the perspectives of pre-start preparation, starting method selection, operation monitoring, and common problem handling, to help users avoid risks and extend equipment life.

I. Necessary checks before starting

1. Electrical system check

- Power supply voltage matching:

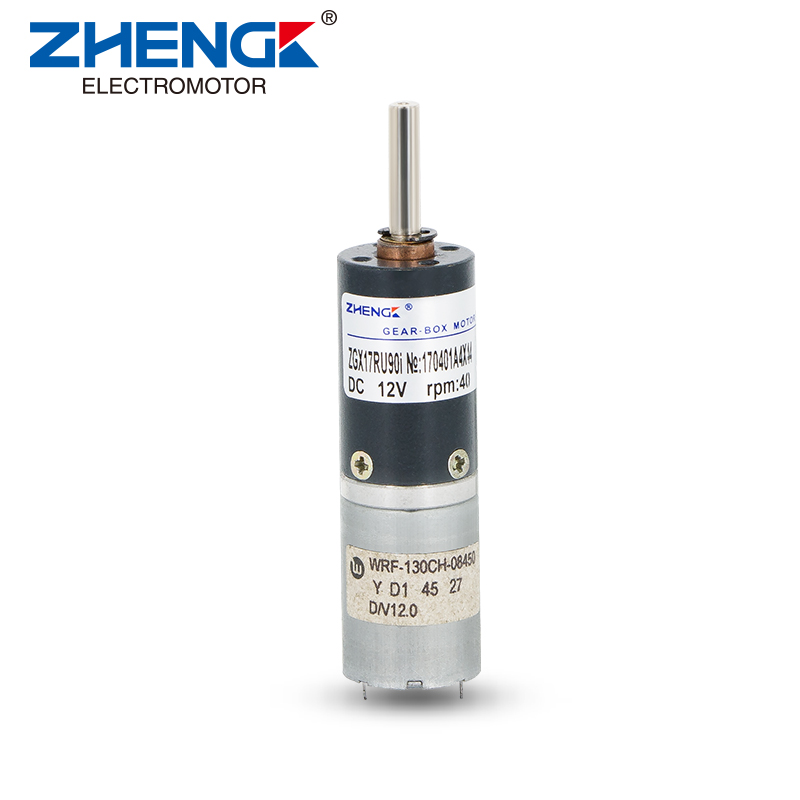

Confirm that the rated voltage of the motor is the same as the power supply voltage (e.g. 12V, 24V, 48V). If the voltage is too high, the insulation layer may be broken; if the voltage is too low, the starting torque will be insufficient.

- Wiring terminal check:

Ensure that the positive and negative poles are wired correctly (DC motor reversal may damage the commutator), and tighten the terminal screws to avoid arcing caused by poor contact.

- Brush and commutator condition:

- Brush length should be greater than 1/3 of the original size, with no cracks on the surface.

- The surface of the commutator should be smooth without an oxidized layer (fine sandpaper can be used to remove the oxidized film).

2. Mechanical system inspection

- Bearing lubrication:

Check whether the bearing grease is sufficient (lithium grease is recommended), and manually rotate the motor shaft to confirm that there is no stagnation or abnormal noise.

- Load connection:

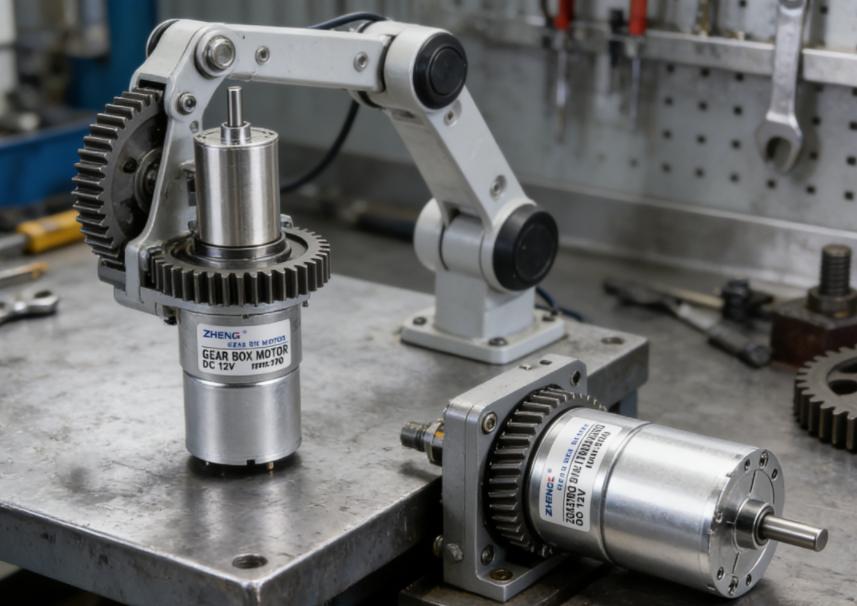

Disconnect the load and try to start, if no-load is normal but failed to start with load, need to check the coupling alignment, belt tension or gear meshing status.

- Heat dissipation conditions:

Ensure that the motor ventilation holes are not blocked, high temperature environment (>40 ℃) need to add cooling fan.

3. Confirmation of environmental conditions

- Humidity control:

Ambient humidity ≤ 80%, prevent short circuit caused by condensation on the surface of commutator.

- Explosion-proof requirements:

Flammable and explosive places should use explosion-proof DC motor (such as Ex d IIB T4 grade).

II. The key monitoring items during the startup process

1. Current monitoring

- Normal phenomenon:

The starting instantaneous current is high but should fall back to the rated value within 0.5 seconds (e.g. motor with rated current 5A, starting current ≤ 50A).

- Abnormal treatment:

- Continuously high current: stop the machine immediately and check whether it is blocked or short-circuited.

- Current fluctuation: check the stability of the power supply or brush contact failure.

2. Speed and torque feedback

- Normal state:

Motor Speed should rise smoothly to the set value, with no violent fluctuations (such as 12V motor no-load speed deviation ≤ ± 5%).

- Abnormal phenomenon:

- Speed cannot reach the rated value: maybe a too-heavy load, insufficient voltage, or worn brushes.

- Periodic fluctuations in speed: Check whether the commutator is eccentric or the winding is locally short-circuited.

3. Temperature and Noise

- Temperature threshold:

- Winding temperature ≤ insulation class limit (e.g., Class B ≤ 130 ℃, Class F ≤ 155 ℃).

- Shell temperature rise ≤ 40 ℃ (and ambient temperature difference).

- Noise diagnosis:

- Uniform “humming” sound: normal electromagnetic noise.

- Sharp friction sound: bearing oil shortage or brush pressure is too high.

- Irregular impact sound: rotor dynamic balance or loose coupling.

III. Common starting problems and solutions

1. The motor fails to start

- Possible causes:

- Power supply not connected or fuse blown.

- Poor contact between brushes and commutator (excessive contact resistance).

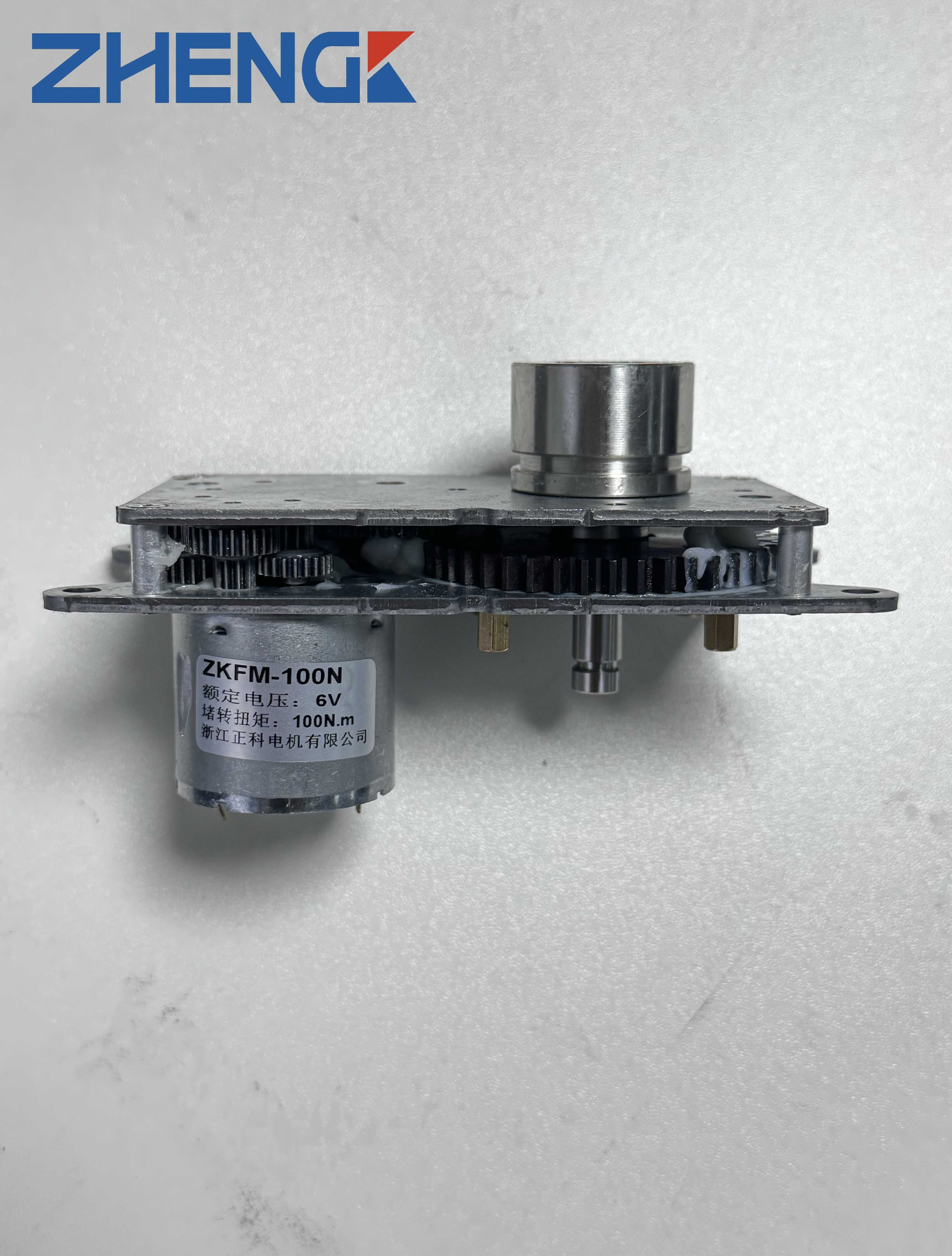

- Load jammed (e.g., a foreign object stuck in the gearbox).

- Solution steps:

1. Measure whether the voltage at the input is normal.

2. Disconnect the load and test whether it can start with no load. 3.

3. Clean the commutator and adjust the brush spring pressure (recommended 15-25kPa).

2. Overheating immediately after startup

- Possible causes:

- Prolonged blocking or overload operation.

- Failure of cooling fan or poor ventilation.

- Short circuit between turns of the winding (insulation resistance ≥1MΩ should be detected by megohmmeter).

- Solution steps:

1. Check whether the load exceeds the rated torque of the motor. 2.

2. Clean the motor cooling hole or replace the fan. 3.

3. Send the motor to a professional service center to test the winding.

3. Commutator spark is too large

- Possible cause:

- Mismatch between brush material and commutator (e.g. graphite brush with copper commutator).

- Motor vibration causes brush jumping.

- The surface of the commutator is oxidized or eccentric.

- Solution steps:

1. Replace the silver graphite brushes (copper content ≥ 50%). 2. reinforce the motor mounting base.

2. Reinforce the motor mounting base to reduce vibration. 3.

3 Repair the commutator roundness by turning (radial runout ≤ 0.02mm).

IV. Safety operation norms

1. Personal protection

- Wear insulated gloves and goggles during operation to prevent arc burns.

- Long hair and loose clothing should be tightened to avoid getting involved in the rotating parts.

2. Emergency shutdown procedure

- If any of the following occurs, please stop the machine immediately:

- Smoke or odor.

- Smoke or odor. The sudden increase in abnormal noise or vibration.

- Ammeter, thermometer pointer over range.

- Operating Procedure:

1. Cut off the main switch of the power supply. 2.

2. Hang the “no closing” warning sign. 3.

3. Wait for the motor to cool down before troubleshooting.

3. Operation Training and Records

- Train operators to recognize abnormal motor conditions on a regular basis.

- Establish a start-up log to record the voltage, current, temperature, and other parameters of each start-up.

The start-up phase of DC motors is a key link in guaranteeing their long-term stable operation. Through rigorous pre-startup inspection, scientific selection of startup mode, real-time operation monitoring, and fast fault response, the equipment failure rate can be significantly reduced and the service life can be extended.