Why is the Gear Ratio of a Gear Motor So Important?

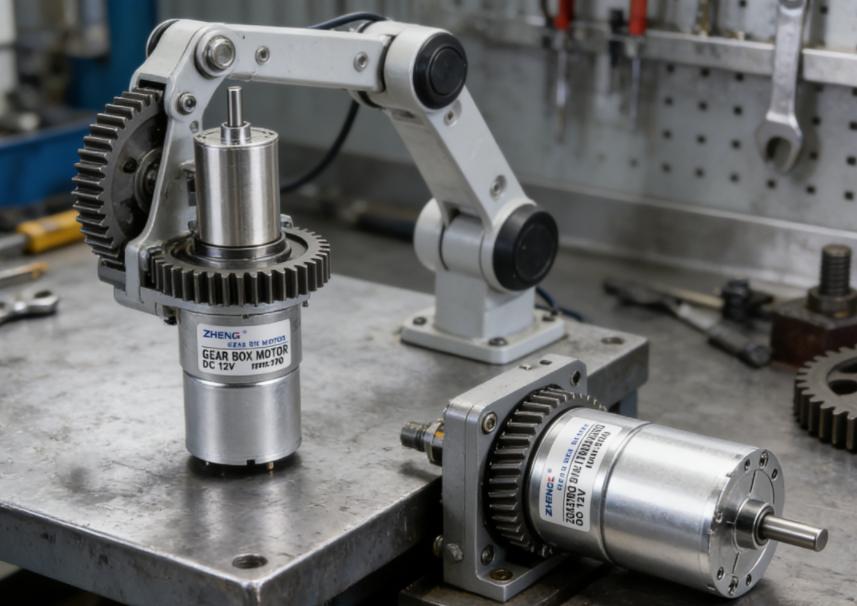

In the world of automation, robotics, and industrial machinery, Gear Motors play a crucial role in converting electrical energy into mechanical motion. One of the most important aspects of agear motor is its gear ratio, which significantly impacts its performance, efficiency, and suitability for different applications. But why is the gear ratio so important?

Understanding Gear Ratio

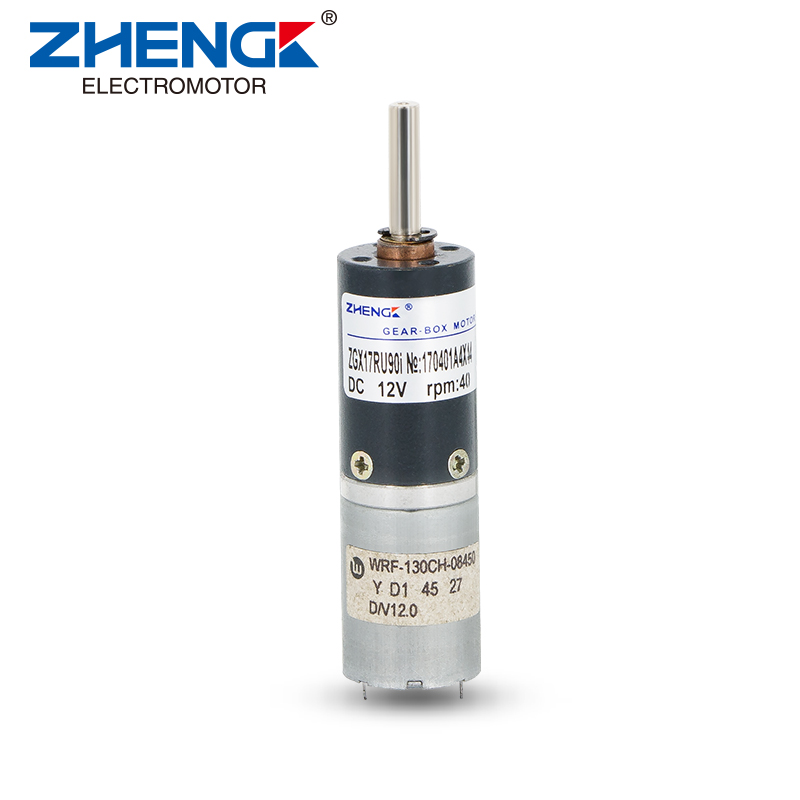

The gear ratio is the relationship between the input speed (motor RPM) and the output speed (shaft RPM). A higher ratio means the output speed is reduced while torque is increased, whereas a lower ratio allows for higher speed but lower torque. Selecting the right gear ratio is essential for optimizing performance based on the specific application.

Key Benefits of an Gear Ratio

1. Increased Torque Output

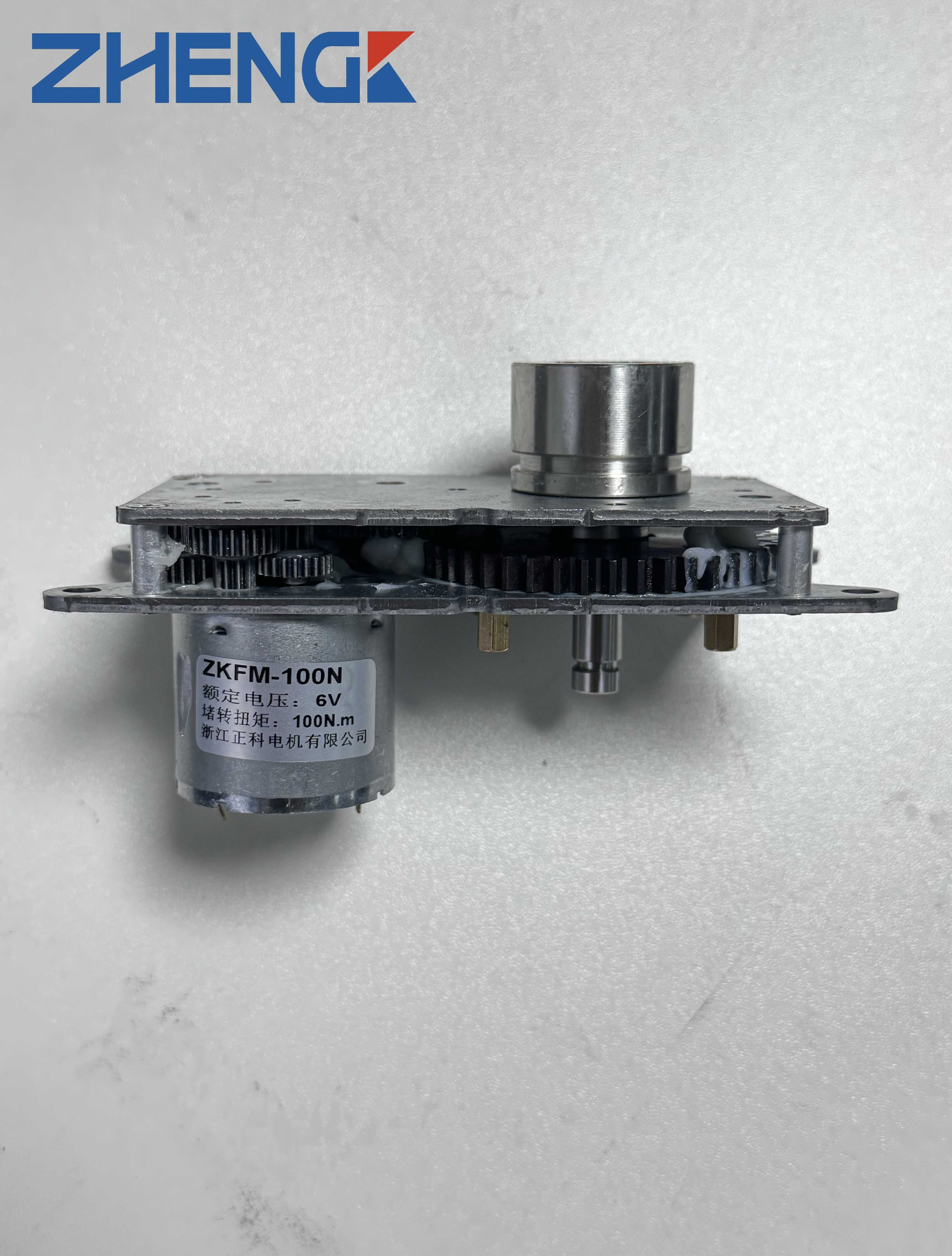

One of the primary functions of a gear motor is to enhance torque. A high gear ratio reduces speed but significantly increases the torque, which is essential for applications requiring strong force, such as conveyor systems, lifting mechanisms, and industrial machinery.

2. Precision and Control

In applications where precise movement is required, such as robotics or medical devices, a well-selected gear ratio ensures smooth and controlled operation. It reduces fluctuations and enhances stability in motion control.

3. Energy Efficiency

An optimized gear ratio allows the motor to operate within its ideal efficiency range. This reduces energy consumption, minimizes heat generation, and extends the lifespan of the motor and its components.

4. Load Handling Capability

Different applications demand different load-handling capabilities. A properly selected gear ratio ensures that the motor can handle the required load without excessive strain, reducing wear and improving reliability.

5. Speed Adaptability

Gear motors with different ratios provide flexibility in achieving the desired speed output. Whether for high-speed automation or slow, powerful mechanical movement, the right gear ratio makes all the difference.

The gear ratio is calculated using the following formula:

Gear Ratio=Input Speed (RPM)/Output Speed (RPM)

Alternatively, if the number of teeth on the gears is known, the ratio can be determined by:

Gear Ratio=Number of Teeth on the Large Gear/Number of Teeth on the Small Gear

Example 1: Using Input and Output Speed

Suppose a motor has an input speed of 3000 RPM, and after passing through a gearbox, the output speed is reduced to 300 RPM. The gear ratio is:

3000/300=10:1

This means the output speed is reduced 10 times, while the output torque is theoretically increased 10 times.

Example 2: Using Gear Teeth Count

Consider a gear system with two gears:

The driving gear (small gear) has 20 teeth

The driven gear (large gear) has 80 teeth

The gear ratio is:

80/20=4:1

This means that for every 4 rotations of the motor, the output shaft completes 1 rotation, while the torque is theoretically increased 4 times.

The gear ratio of a gear motoris a critical factor that determines its performance, efficiency, and application suitability. Whether you need High Torque, precise control, or energy efficiency, choosing the right gear ratio ensures smooth and reliable operation. When selecting a gear motor, consider your project's specific requirements to achieve the best results. Selecting the best gear ratio depends on factors such as torque requirements, speed needs, load weight, and operational efficiency. Understanding these aspects ensures that your system runs optimally, improving productivity and reducing maintenance costs.